Product Description

Wheel Loader Sun Gear for CHINAMFG CHINAMFG Foton

| NAME | MODEL | NOTE | |

| oil filter | Engine Model C6121 | ||

| Fuel Filter | Engine Model C6121 | ||

| Air Filter | Engine Model WD615 WD10 | ||

| oil filter | Engine Model WD615 WD10 | ||

| Fuel Filter | Engine Model WD615 WD10 | ||

| Fuel Filter | Engine Model WD615 WD10 | ||

| Air Filter | Engine Model TD226B | ||

| oil filter | Engine Model TD226B | ||

| Fuel Filter | Engine Model TD226B | ||

| Filter | hydraulic system | ||

| transmission filter | ZF4WG180 4WG200 | ||

| convert filter | |||

| back oil filter | FL936 | ||

| back oil filter | |||

| filter | |||

| combination lamp switch | |||

| Left Front Lamp | |||

| Right Front Lamp | |||

| hand brake valve | |||

| power switch | |||

| combination valve | FL936 FL958 FL956 | ||

| door lock | FL936 FL958 FL956 | ||

| stater switch | FL936 FL958 FL956 | ||

| Air-conditioning compressor | FL936 FL958 FL956 | ||

| steering cylinder seal kit | FL958G | ||

| Bucket cylinder seal kit | FL958G | ||

| Boom cylinder seal kit | FL958G | ||

| steering cylinder seal kit | FL956 | ||

| Bucket cylinder seal kit | FL956 | ||

| Boom cylinder seal kit | FL956 | ||

| steering cylinder seal kit | FL936 | ||

| Bucket cylinder seal kit | FL936 | ||

| Boom cylinder seal kit | FL936 | ||

| MIRROR (with Frame) | FL936 FL958 FL956 | ||

| MIRROR (without Frame) | FL936 FL958 FL956 | ||

| air booster pump | FL936 | ||

| brake pads(stype 1) | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| brake pads(stype 2) | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| brake caliper (stype 1) | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| brake caliper (stype 2) | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| Brake caliper piston (stype 1) | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| Brake caliper piston (stype 2) | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| FRONT DRIVEN SHAFT | FL936 | ||

| MIDDLE DRIVEN SHAFT support | FL936 | ||

| REAR DRIVEN SHAFT | FL936 | ||

| MAIN DRIVEN SHAFT | FL936 | ||

| speed pump | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ZL40 50 | |

| speed control valve | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ZL40 50 | |

| input gear | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ZL40 50 transmission | |

| over clutch assy | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ZL40 50 transmission | |

| oil pan | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ZL40 50 transmission | |

| widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ZL40 50 transmission | ||

| widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ZL40 50 transmission | ||

| driving shaft, steering punp | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ZL40 50 transmission | |

| shaft gear | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ZL40 50 transmission | |

| first gear piston | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| first gear inner rim | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| sun gear | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| frictional plate spacing bracket | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| pinion carrier astern | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| piston | widely used for CHINAMFG CHINAMFG CHINAMFG XGMA… | ||

| thrust plate | |||

| driving plate | |||

| cylinder | |||

| transmission gasket seal kit | used for CHINAMFG CHINAMFG CHINAMFG LONKING… | ||

| brake disk | FL958 FL956 CHINAMFG LG956 LG958 LG953 | ||

| brake disk | FL936 CHINAMFG LG936 | ||

| brake disk | FL936 LW300FN | ||

| PLANET PINION CARRIER | FL956 FL958 CHINAMFG LG956 | ||

| PLANET PINION CARRIER | FL936 LG936 | ||

| PLANET GEAR | FL956 FL958 CHINAMFG LG956 | ||

| PLANET GEAR | FL936 LG936 | ||

| PLANET PINION SHAFT | FL956 FL958 CHINAMFG LG956 | ||

| PLANET PINION SHAFT | FL936 LG936 | ||

| ROLLER PIN 5X45 | FL956 FL958 CHINAMFG LG956 | ||

| ROLLER PIN 4X38 | FL936 LG936 | ||

| sun gear | FL956 FL958 CHINAMFG LG956 | ||

| sun gear | FL936 LG936 | ||

| bolt and nut for Wheel rim | FL956 FL958 CHINAMFG LG956 | ||

| bolt and nut for Wheel rim | FL936 LG936 | ||

| AXLE RING GEAR | FL956 FL958 CHINAMFG LG956 | ||

| AXLE RING GEAR | FL936 LG936 | ||

| FRONT MAIN DRIVE | FL956 FL958 CHINAMFG LG956 | ||

| FRONT MAIN DRIVE | LG936 | ||

| FRONT MAIN DRIVE | FL936 | ||

| bevel gear assy | FL956 FL958 CHINAMFG LG956 | ||

| bevel gear assy | LG936 | ||

| bevel gear assy | FL936 | ||

| GEAR PINION | FL956 FL958 CHINAMFG LG956 | ||

| GEAR PINION | LG936 | ||

| GEAR PINION | FL936 | ||

| half shaft gear | FL956 FL958 CHINAMFG LG956 | ||

| half shaft gear | LG936 | ||

| half shaft gear | FL936 | ||

| CROSS AXLE | FL956 FL958 CHINAMFG LG956 | ||

| CROSS AXLE | LG936 | ||

| CROSS AXLE | FL936 | ||

| differential assy | FL956 FL958 CHINAMFG LG956 | ||

| differential assy | LG936 | ||

| differential assy | FL936 | ||

| air booster pump | FL958 FL956 | ||

| air booster pump | FL936 | ||

| air booster pump | SDLG LG933 LG936 | ||

| air booster pump | SDLG LG953 LG956 LG958 | ||

| engine oil pressure sensor | FL958 FL956 | ||

| reverse light switch | FL956 FL958 FL936 | ||

| reverse horn | FL956 FL958 FL936 | ||

| speaker horn | FL956 FL958 FL936 | ||

| air pressure meter | SDLG CHINAMFG CHINAMFG CHINAMFG ALL USED | ||

| Voltage Meter | SDLG CHINAMFG CHINAMFG CHINAMFG ALL USED | ||

| engine oil pressure | SDLG CHINAMFG CHINAMFG CHINAMFG ALL USED | ||

| fuel meter | SDLG CHINAMFG CHINAMFG CHINAMFG ALL USED | ||

| water temperature meter | SDLG CHINAMFG CHINAMFG CHINAMFG ALL USED | ||

| Oil temperature meter | SDLG CHINAMFG CHINAMFG CHINAMFG ALL USED | ||

| alternator | FL936 LG936 | ||

| alternator | FL956 FL958 LG953 LG956 LG958 | ||

| alternator | FL958G LG956L | ||

| stater | FL936 LG936 | ||

| stater | FL956 FL958 LG953 LG956 LG958 | ||

| stater | FL958G LG956L | ||

| upper hinge pin | FL936 | Frame Hinged system | |

| cover for upper hinge pin | FL936 | ||

| nut for upper hinge pin | FL936 | ||

| seal for upper hinge pin | FL936 | ||

| lower hinge pin | FL936 | ||

| seal for lower hinge pin | FL936 | ||

| cover for lower hinge pin | FL936 | ||

| bearing for upper and lower hinge pins | FL936 | ||

| upper hinge pin | FL958 | ||

| lower hinge pin | |||

| Break Pads | SDLG CHINAMFG CHINAMFG CHINAMFG LONKING | ||

| Break Pads | SDLG CHINAMFG CHINAMFG CHINAMFG LONKING | ||

| Break Pads | ONLY FOR LiuGong | ||

| Break Caliper | SDLG CHINAMFG CHINAMFG CHINAMFG LONKING | ||

| Break Caliper | SDLG CHINAMFG CHINAMFG CHINAMFG LONKING | ||

| Break Caliper | ONLY FOR LiuGong | ||

| middle teeth | LiuGong ZL50C CLG856 CLG862 | ||

| right side teeth | LiuGong ZL50C CLG856 CLG862 | ||

| left side teeth | LiuGong ZL50C CLG856 CLG862 | ||

| teeth sleeve | LiuGong ZL50C CLG856 CLG862 | ||

| widely Used For CHINAMFG CHINAMFG CHINAMFG …5T Wheel loader | Head gasket | ||

| widely Used For CHINAMFG CHINAMFG CHINAMFG …5T Wheel loader | All The Seal Kit | ||

| widely Used For CHINAMFG CHINAMFG CHINAMFG …5T Wheel loader | Head gasket | ||

| widely Used For CHINAMFG CHINAMFG CHINAMFG …5T Wheel loader | All The Seal Kit | ||

| widely Used For CHINAMFG CHINAMFG CHINAMFG …3T Wheel loader | Head gasket | ||

| widely Used For CHINAMFG CHINAMFG CHINAMFG …3T Wheel loader | All The Seal Kit | ||

| widely Used For CHINAMFG CHINAMFG CHINAMFG …3T Wheel loader | Head gasket | ||

| widely Used For CHINAMFG CHINAMFG CHINAMFG …3T Wheel loader | All The Seal Kit |

HangZhou CHINAMFG Mechanical & Electrical Equipment Co. Ltd, the authorized dealer of

Cummins (China) Investment Co., Ltd (CCI), established in 2015 by Mr. Jordan Wang who had rich experience in CHINAMFG engine, CHINAMFG generator and related market, especially mine, O&G, marine, construction machinery, etc., as a sales director,Jordan worked in CHINAMFG for 8 years.

Raptors specializes in supplying CHINAMFG all series genuine parts and engine whole goods, such as B/QSB3.3, ISF2.8/3.8, ISG, ISB/QSB4.5, 6BT,6CT, ISB/QSB6.7,QSL9, QSM/ISM/M11, NTA855, QSX15, QSK19, QSK23, VTA28, QST30, KTA19, KTA38, KAT50, QSK60,QSK78,etc;

Jordan had been responsible for mine market for 4 years during working in CHINAMFG china, so CHINAMFG has very good relationship with CHINAMFG who is the joint venture with TEREX, could supply CHINAMFG parts, such as parts for 3305, 3307, TR50, TR60, TR100, and MT3600, MT3700, NTE150, NTE200, NTE240, NTE260; also supplying construction machinery parts from SANY, XCMG, LIUGONG, XIHU (WEST LAKE) DIS., SDLG, CHINAMFG and CHINAMFG etc.

Raptors, located in No. 789, Xihu (West Lake) Dis. Road, East of Xihu (West Lake) Dis. Industry, HangZhou, ZheJiang ,

China (Mainland), is just 2 km away from CHINAMFG (China) Investment Co., Ltd,

HangZhou Branch, We could make sure the fast delivery and enough inventories, also reasonable price.

Our business scopes:

1, CHINAMFG genuine parts and engine overhaul

2, ZheJiang Fleet guard filters and US Fleet guard filters.

3, HOLSET turbocharger series

4, China CHINAMFG parts series

5, construction machinery parts

Various shipment ways.

Thanks for the high quality, fast delivery, reasonable price, CHINAMFG already exported to Finland, Sweden, Germany, Netherland, Czech Republic, France, Romania,

Malaysia, Indonesia, Thailand, Libya, UAE, IRAN, Algeria, etc. if interested in any of our products, please contact us right now; we are always serving you at any time. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Double Helical Gear |

| Material: | Cast Iron |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you describe the interaction between sun gears and planet gears?

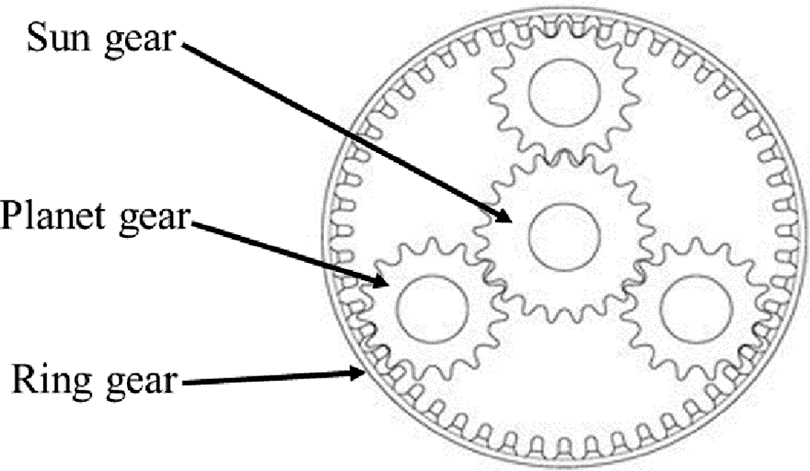

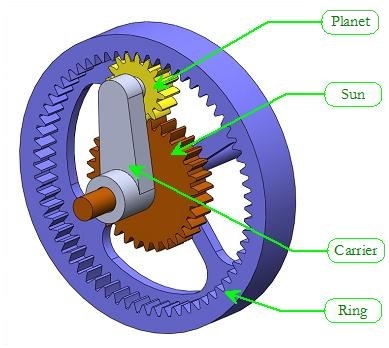

The interaction between sun gears and planet gears is a fundamental aspect of gear systems. Let’s delve into the details of this interaction:

- Planetary Gear Systems:

The interaction between sun gears and planet gears primarily occurs in planetary gear systems. These systems consist of multiple planet gears that rotate around a central sun gear while meshing with an outer ring gear. This arrangement allows for various mechanical advantages and functionalities.

- Power Transmission:

The sun gear serves as the primary driver in a planetary gear system. When power is applied to the sun gear, it transmits rotational force to the planet gears. The planet gears, due to their meshing with both the sun gear and the ring gear, distribute the transmitted power evenly across all the gears.

As the sun gear rotates, the planet gears rotate in the opposite direction around the sun gear while also rotating around their own axes. This rotational movement of the planet gears, driven by the sun gear, plays a crucial role in power transmission within the gear system.

- Speed and Torque Ratios:

The interaction between the sun gear and planet gears affects the speed and torque ratios in a gear system. By choosing different sizes for the sun gear and planet gears, engineers can manipulate the gear ratios to achieve specific outcomes.

When the sun gear is larger than the planet gears, it results in a higher speed ratio. In this case, the sun gear rotates faster than the planet gears, leading to an output shaft or ring gear with increased rotational speed relative to the input shaft or sun gear.

Conversely, when the sun gear is smaller than the planet gears, it leads to a lower speed ratio. In this scenario, the sun gear rotates slower than the planet gears, resulting in an output shaft or ring gear with reduced rotational speed compared to the input shaft or sun gear.

Similarly, the interaction between the sun gear and planet gears affects the torque ratio. When the sun gear is larger than the planet gears, it amplifies the torque, resulting in higher output torque relative to the input torque. Conversely, when the sun gear is smaller, it reduces the torque, resulting in lower output torque compared to the input torque.

- Direction Reversal:

The interaction between the sun gear and planet gears also enables torque direction reversal in planetary gear systems. When the sun gear rotates in a specific direction, it imparts torque to the planet gears, causing them to rotate in the opposite direction around the sun gear.

This counterclockwise rotation of the planet gears, as driven by the sun gear, leads to the ring gear rotating in the opposite direction. By reversing the direction of the sun gear’s rotation, the torque direction can be reversed once again. This ability to change torque direction makes planetary gear systems versatile and applicable in various mechanical and automotive applications.

- Mechanical Advantages:

The interaction between sun gears and planet gears offers several mechanical advantages. The distribution of torque across multiple planet gears allows for increased load-bearing capacity and improved system reliability. As each planet gear shares the load, the overall stress on individual gears is reduced, enhancing the system’s durability.

Moreover, the arrangement of sun gears and planet gears in a planetary gear system results in compact designs and high power density. The distributed power transmission and torque-sharing characteristics enable the system to handle higher loads while occupying minimal space.

In summary, the interaction between sun gears and planet gears in planetary gear systems is crucial for power transmission, achieving speed and torque ratios, enabling torque direction reversal, and providing mechanical advantages such as load distribution and compact designs. Understanding this interaction is essential for designing and optimizing gear systems in various applications.

How does a sun gear handle variations in load and speed conditions?

A sun gear is designed to handle variations in load and speed conditions in mechanical systems. Its unique positioning and interaction within a planetary gear arrangement contribute to its ability to adapt to changing load and speed requirements. Here’s an explanation of how a sun gear handles variations in load and speed conditions:

- Load Distribution:

In a planetary gear system, the sun gear is located at the center and engages with multiple planet gears, which in turn interact with the outer ring gear. This configuration enables the sun gear to distribute the load among the planet gears. As the load on the system varies, the distribution of load among the planet gears adjusts accordingly. The load distribution mechanism allows the sun gear to handle variations in load conditions by effectively sharing the load across multiple contact points.

- Torque Amplification:

The arrangement of the sun gear, planet gears, and ring gear in a planetary system allows for torque amplification. By changing the number of teeth on the gears and their relative sizes, the gear ratio can be customized. This capability enables the sun gear to adapt to variations in load and speed conditions. When higher torque is required, the gear system can be configured to provide torque amplification by increasing the gear ratio. Conversely, when lower torque is needed, the gear ratio can be adjusted accordingly. This flexibility in gear ratio configuration allows the sun gear to handle variations in load and speed by adapting the torque output.

- Speed Regulation:

Another way the sun gear handles variations in load and speed conditions is through speed regulation. In a planetary gear system, the sun gear’s rotation speed is determined by the input speed and the gear ratio configuration. By adjusting the gear ratio, the rotational speed of the sun gear can be controlled. This speed regulation capability allows the sun gear to adapt to changing speed requirements. When higher speeds are necessary, the gear ratio can be adjusted to increase the rotational speed of the sun gear. Similarly, when lower speeds are desired, the gear ratio can be modified accordingly. The sun gear’s ability to regulate its rotational speed enables it to accommodate variations in load and speed conditions.

- Sturdy Construction:

Sun gears are typically constructed from durable materials such as hardened steel or other high-strength alloys. This robust construction enables them to withstand the forces generated by variations in load and speed conditions. The sturdy design of sun gears ensures that they can handle the stresses and strains associated with changing operating conditions without experiencing premature wear or failure.

In summary, a sun gear handles variations in load and speed conditions through load distribution among the planet gears, torque amplification or reduction based on the gear ratio configuration, speed regulation by adjusting the gear ratio, and its sturdy construction. These features enable the sun gear to adapt to changing requirements, ensuring reliable and efficient operation in various mechanical systems.

How does a sun gear affect the overall gear ratio in a system?

The presence and characteristics of a sun gear play a significant role in determining the overall gear ratio in a system. Understanding how the sun gear affects the gear ratio helps in analyzing and designing gear systems with the desired performance. Here’s an explanation of how a sun gear affects the overall gear ratio in a system:

- Number of Teeth: The number of teeth on the sun gear influences the gear ratio. In a simple gear system, where the sun gear engages with a single gear, the gear ratio is determined by the ratio of the number of teeth on the two gears. For example, if the sun gear has 10 teeth and the other gear has 30 teeth, the gear ratio would be 1:3, meaning the output gear rotates three times slower than the sun gear.

- Arrangement with Other Gears: In more complex gear systems, such as planetary gear configurations, the arrangement of the sun gear with other gears further influences the gear ratio. In a planetary gear set, the sun gear engages with multiple planet gears and an outer ring gear. By manipulating the sizes and arrangements of these gears, a wide range of gear ratios can be achieved. For instance, if the sun gear is fixed, the ring gear becomes the output and the gear ratio is determined by the relative sizes of the sun gear, planet gears, and ring gear.

- Planet Gears: The number of planet gears in a planetary gear system also affects the gear ratio. Increasing or decreasing the number of planet gears alters the gear ratio by changing the load distribution and the interaction between the sun gear and the ring gear. More planet gears generally result in a higher gear ratio, while fewer planet gears tend to reduce the gear ratio.

- Epicyclic Gear Trains: The arrangement of gears in an epicyclic gear train, which includes the sun gear, planet gears, and ring gear, allows for even more complex gear ratios. By fixing or holding certain gears while others are driven, various gear ratios can be achieved. For example, fixing the ring gear and driving the sun gear produces a different gear ratio compared to fixing the sun gear and driving the ring gear.

- Variable Gear Ratio: In some systems, the gear ratio can be varied by changing the position or speed of the sun gear. This can be achieved using mechanisms such as adjustable clutches or continuously variable transmissions (CVTs). By modifying the engagement between the sun gear and other gears, the gear ratio can be adjusted to optimize performance for different operating conditions.

In summary, the presence and characteristics of a sun gear, including the number of teeth, its arrangement with other gears, the presence of planet gears, and the overall gear system configuration, all contribute to the determination of the gear ratio. Understanding these factors allows for the design and control of gear systems with specific gear ratios to meet the requirements of various mechanical applications.

editor by CX 2024-01-11