Product Description

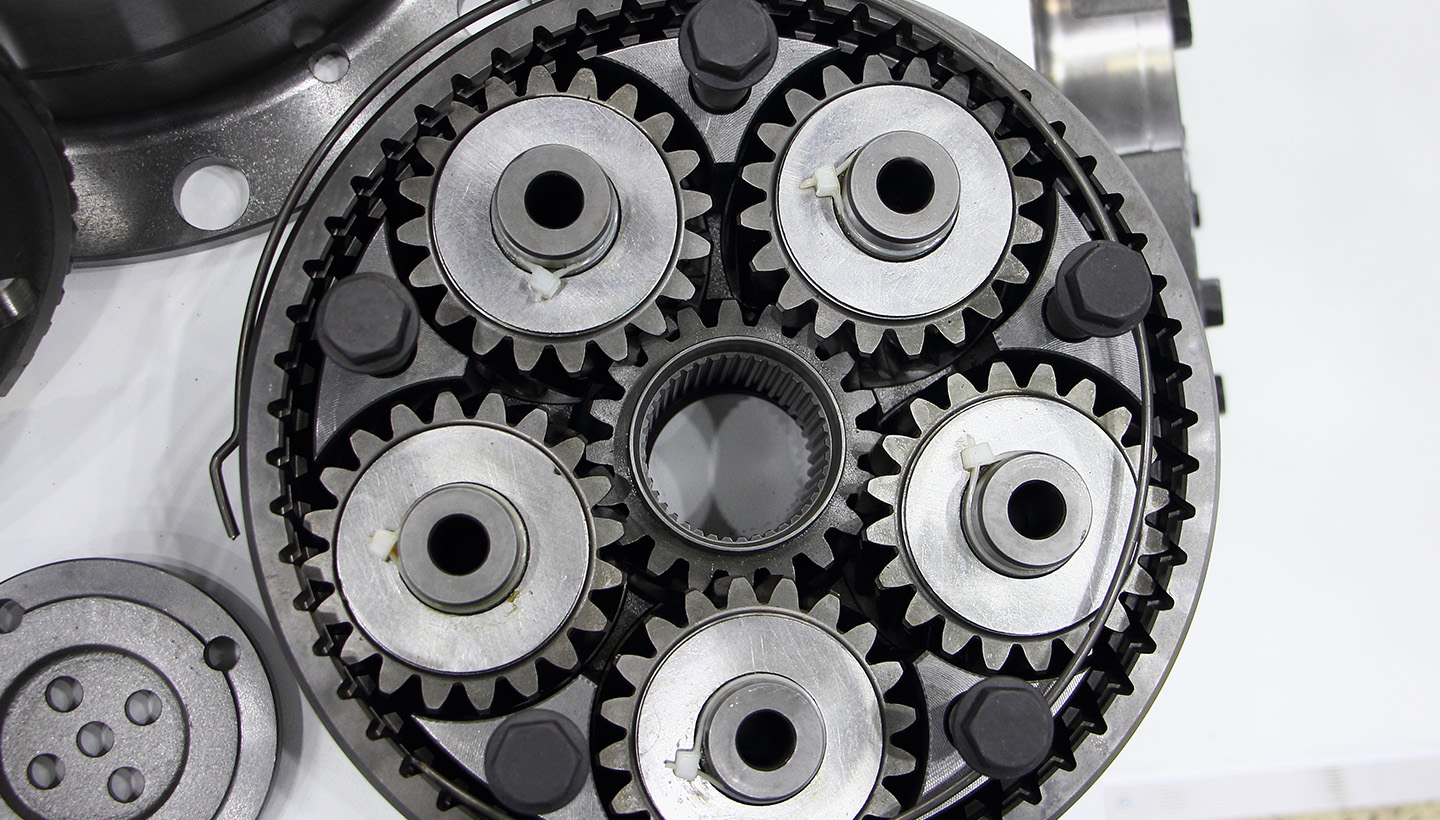

Transmission System Spare Parts Sun gear for wheel loader LG936L/LG956L L956F

[Our services

1.Mining &Construction machinery:

**Wheel loader

LG916 LG918 L918 LG933L L933 LG936L LG938L L938F LG946L L948 L948F LG952N LG952H LG953N L953F L955 L955F L955FN LG956L L956F L956FH LG958L L958F LG959 LG968 L968F LG978 LG979

**Backhoe loader

LGB877 LGB876 WZ30-25

**Motor Grader

G9138 G9165 G9180 G9190 G9200 G9220

**Road Roller

RS7120 RS7200 RS7260 RS8140 RS8160 RS8180 RS8200 RS8220

**Excavator

LG6135E LG6150E LG6210E LG6225E LG6235E LG6250E LG6300E LG6360E LG6400E

** Bulldozer

SD16 TY160 /SD22 TY220/ SD32 TY320

2.Engine parts

(Yuchai(YC6108G) CHINAMFG (Deutz TD226B,WD615) Shangchai (C6121),(6BT5.9..)

3.Transmission

(4WG180,4WG200..) HangZhou advance (ZL30E,ZL50E,YD13,WG180..)

[Customer&Exhibition]

Any interests, feel free to contact me!

| Type: | Sun Gear |

|---|---|

| Application: | Wheel Loader |

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Stock: | Available |

| Part Number: | 3030900153 |

What are the safety considerations when working with sun gears in machinery?

Working with sun gears in machinery requires careful attention to safety to prevent accidents and ensure the well-being of operators. Here are some important safety considerations when working with sun gears:

- Training and Knowledge:

Operators and maintenance personnel should receive proper training and have a thorough understanding of the machinery’s operation and the specific risks associated with working with sun gears. This includes knowledge of safety procedures, maintenance protocols, and the use of personal protective equipment (PPE).

- Lockout/Tagout Procedures:

Before performing any maintenance or repair tasks on machinery involving sun gears, it is essential to follow lockout/tagout procedures. These procedures involve isolating the machinery from its power source and ensuring that it cannot be accidentally energized during maintenance. Lockout/tagout procedures help prevent unexpected movements of the gears, reducing the risk of injury.

- Personal Protective Equipment (PPE):

Appropriate personal protective equipment should be worn when working with sun gears. This may include safety glasses, gloves, protective clothing, and hearing protection, depending on the specific hazards present. PPE helps protect operators from potential injuries caused by flying debris, contact with moving parts, and excessive noise.

- Machine Guards:

Machine guards should be in place to prevent accidental contact with the sun gears during operation. Guards can be physical barriers, such as covers or enclosures, that restrict access to the gears. They act as a protective barrier and reduce the risk of entanglement or injury caused by accidental contact with rotating or moving parts.

- Maintenance and Inspection:

Regular maintenance and inspection of machinery, including sun gears, are crucial for identifying potential issues and preventing malfunctions or failures. Maintenance tasks should be carried out following manufacturer guidelines and recommendations. Inspection of gears should include checking for signs of wear, proper lubrication, and alignment.

- Proper Handling and Lifting:

When handling sun gears or transporting them within a facility, proper lifting techniques and equipment should be used. Sun gears can be heavy and require appropriate lifting devices, such as cranes or hoists, to avoid strain or injuries. Operators should also ensure that gears are securely fastened or stored to prevent them from falling or causing accidents.

- Risk Assessment:

A comprehensive risk assessment should be conducted to identify hazards associated with sun gears and their machinery. The assessment should consider factors such as gear size, rotational speed, pinch points, and potential for entanglement. Based on the assessment, appropriate safety measures and controls should be implemented to mitigate identified risks.

- Emergency Procedures:

Clear emergency procedures should be established and communicated to all personnel working with sun gears. These procedures should include protocols for responding to accidents, injuries, or equipment malfunctions. Operators should be familiar with emergency shutdown procedures and know how to safely stop the machinery in case of an emergency.

By adhering to these safety considerations, operators and maintenance personnel can minimize the risk of accidents and promote a safe working environment when working with sun gears in machinery.

How do you calculate gear ratios involving a sun gear in planetary systems?

Calculating gear ratios in planetary systems involving a sun gear requires considering the number of teeth on the gears and their arrangement. Understanding the calculation process helps in determining the gear ratio and predicting the rotational relationship between the input and output gears. Here’s an explanation of how to calculate gear ratios involving a sun gear in planetary systems:

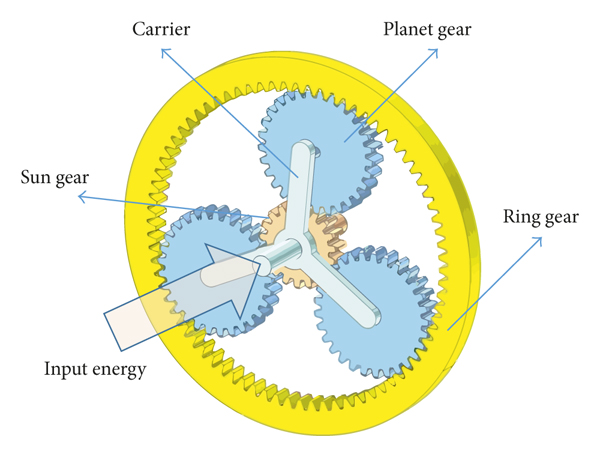

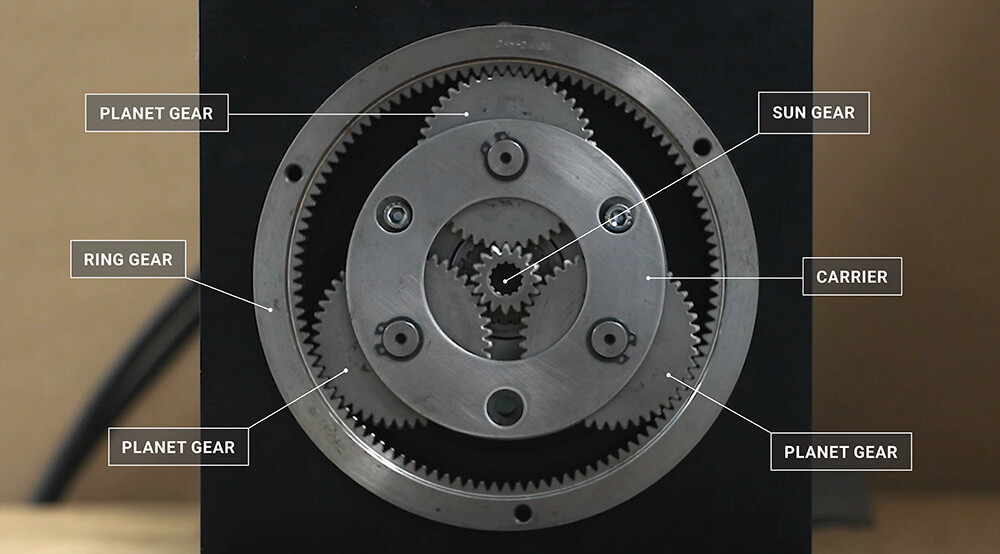

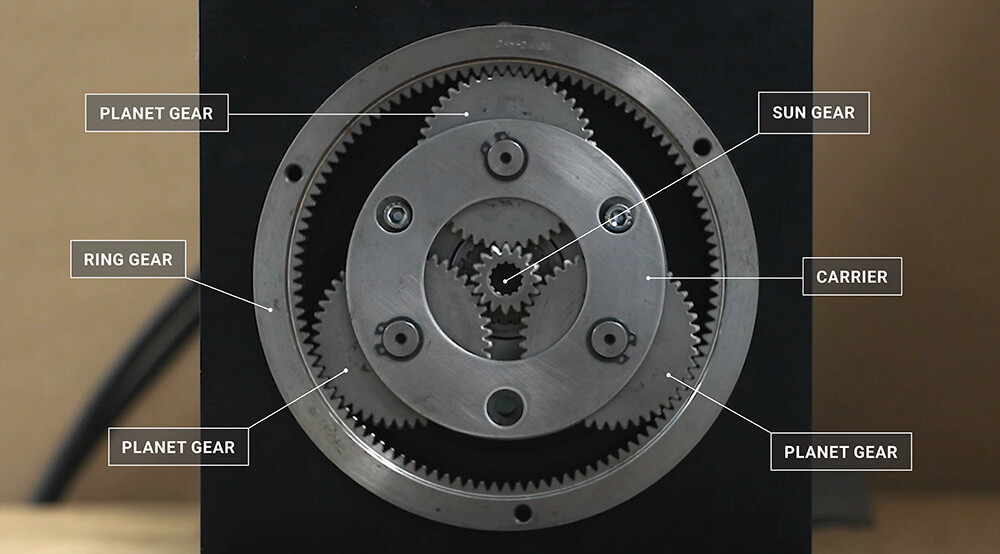

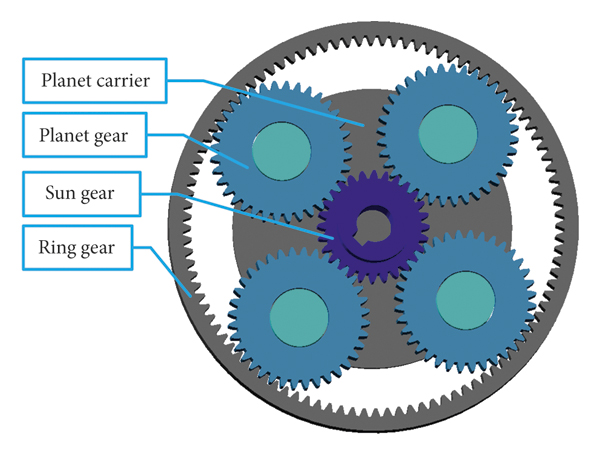

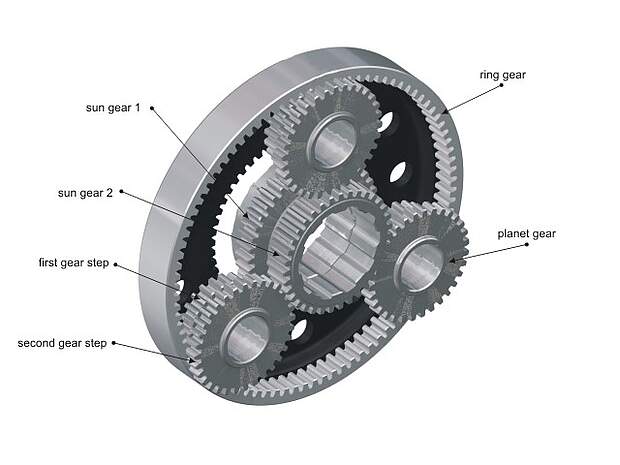

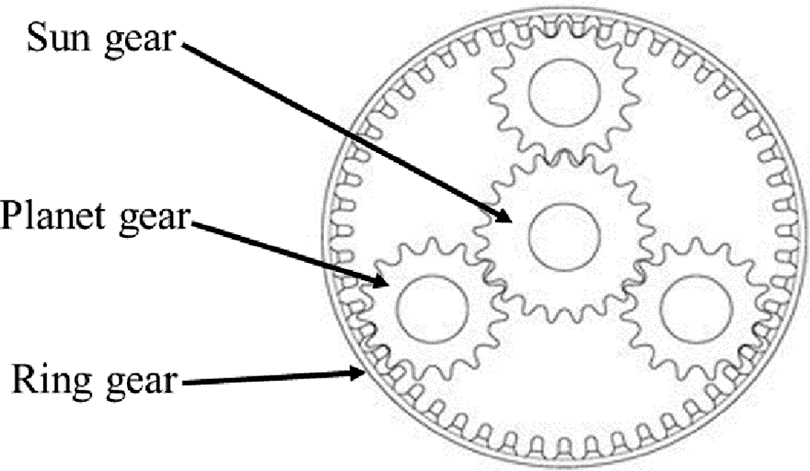

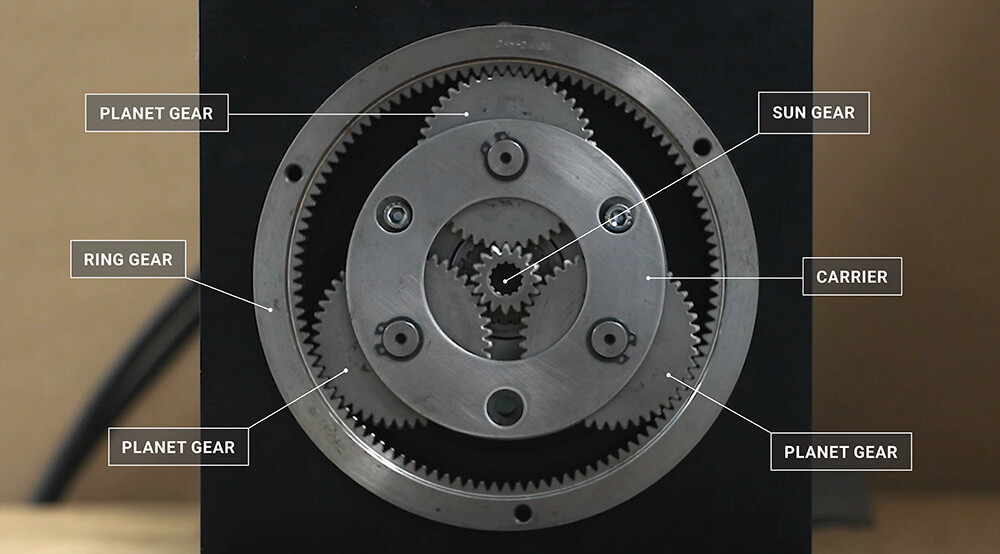

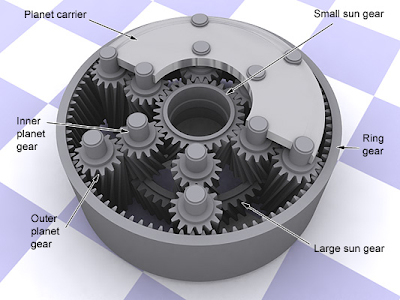

- Step 1: Identify the Gears: In a planetary system, identify the gears involved, namely the sun gear, planet gears, and ring gear. The sun gear is the gear at the center, surrounded by the planet gears, which in turn engage with the outer ring gear.

- Step 2: Count the Teeth: Count the number of teeth on each gear. The sun gear, planet gears, and ring gear all have a specific number of teeth. Let’s denote these as Ts (sun gear teeth), Tp (planet gear teeth), and Tr (ring gear teeth).

- Step 3: Determine the Gear Ratio: The gear ratio in a planetary system involving a sun gear is calculated using the following formula:

Gear Ratio = (Tp + Tr) / Ts

- Step 4: Interpret the Gear Ratio: The calculated gear ratio represents the rotational relationship between the input (sun gear) and output (ring gear) gears. For example, if the gear ratio is 2:1, it means that for every two revolutions of the sun gear, the ring gear completes one revolution in the opposite direction.

- Step 5: Adjust for Multiple Planet Gears or Fixed Components: In some cases, planetary systems may involve multiple planet gears or fixed components. The presence of multiple planet gears affects the gear ratio, and the inclusion of fixed components alters the gear engagement and behavior. These factors may require additional calculations or adjustments to accurately determine the gear ratio.

In summary, calculating gear ratios involving a sun gear in planetary systems necessitates identifying the gears, counting the teeth on each gear, and applying the appropriate formula. The resulting gear ratio provides insights into the rotational relationship between the sun gear and the ring gear. It’s important to consider any additional elements, such as multiple planet gears or fixed components, that may influence the gear ratio calculation.

How does a sun gear differ from other types of gears?

A sun gear has distinct characteristics that set it apart from other types of gears. While gears serve various purposes in mechanical systems, understanding the specific features of a sun gear can help differentiate it from other gear types. Here’s an explanation of how a sun gear differs from other gears:

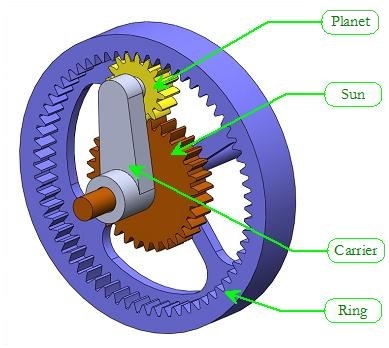

- Central Position: Unlike many other gears that are located on the periphery of a gear system, a sun gear is positioned at the center of a planetary gear arrangement. It serves as a central driver within the system, transmitting torque to other gears.

- Engagement with Planet Gears: A defining feature of a sun gear is its engagement with multiple planet gears. These planet gears surround the sun gear and mesh with both the sun gear and an outer ring gear. The interaction between the sun gear and the planet gears allows for the transfer of torque and power distribution within the gear system.

- Gear System Configuration: Sun gears are commonly found in planetary gear systems, where they function as a central component. Planetary gear systems consist of a sun gear, planet gears, and an outer ring gear. The arrangement and interaction of these gears enable various gear ratios, torque multiplication, and directional control.

- Power Input: In a planetary gear system, the sun gear typically receives power input from an external source, such as an engine or motor. It serves as the primary driving element that initiates torque transmission and power distribution within the system.

- Role in Gear Ratio: The sun gear’s size, number of teeth, and its interaction with the planet gears and ring gear determine the overall gear ratio. By altering the sizes and arrangements of these gears, manufacturers can achieve different speed and torque combinations, providing versatility in gear system applications.

While a sun gear has its unique characteristics, it is essential to note that gears come in various types and configurations, each serving specific purposes in mechanical systems. Different types of gears include spur gears, helical gears, bevel gears, worm gears, and more. Each type has its own design, tooth profile, and applications, catering to different needs such as speed reduction, torque multiplication, directional control, or noise reduction.

In summary, a sun gear differentiates itself through its central positioning, engagement with planet gears, configuration in planetary gear systems, role as a power input element, and influence on gear ratio. Understanding these distinctions helps in recognizing the specific functions and applications of sun gears within mechanical systems.

editor by CX 2023-10-21

China best 90 Flange Precision Speed Gear Reducer Mounting Transmission Planetary Gearbox bicycle planetary gearbox

Product Description

Product Description

The reducer is generally used for low-speed and high-torque transmission equipment.

The motor, internal combustion engine or other high-speed running power is used to achieve the purpose of deceleration by meshing with the large gear on the output shaft through a gear with a small number of teeth on the input shaft of the reducer.

The reducer will also have several pairs of gears with the same principle to achieve the ideal reduction effect.

The ratio of the number of teeth of the large and small gears is the transmission ratio.

|

Applicable Industries |

Manufacturing Plant, Automation industry |

Customized support |

OEM, ODM |

|

Gearing Arrangement |

Planetary |

Output Torque |

≤60 N.m |

|

Input Speed |

≤3000rpm |

Output Speed |

≥43rpm |

|

Place of Origin |

ZheJiang , China |

Brand Name |

HPS |

|

Certification |

ISO9001, CE |

Housing Material |

45#Steel or 42Crmo |

|

Ratio |

4,5,7,10,16,20,25,28,35,40,50,70 |

Material of Shaft |

as required |

|

Model |

SPLF60 |

Lubricant |

Synthetic Grease |

|

Packing |

Standard export package |

Warranty |

1 Year |

Application Field

Automatic Arms

Assembly Line

3D-Printer

Medical -Equipment

CNC Machine

Tapping Machine

Other Automation Devices

Why Choose Us

Standard production and Strict testing process

Package Type: Standard export packing & Wood pallets packing

CERTIFICATIONS

Product Parameters

It is suitable for most servomotor brands manufactured by manufacturers

Company Profile

ZheJiang High Precision Gear Transmission Co., Ltd

ZheJiang High Precision Gear Transmission Co., Ltd located in HangZhou city, ZheJiang Province, China. It is a leading company dedicated in precision transmission parts and system research, manufacture and sales, various series of products are manufactured in its 5000 square CZPT workshop, the precision planetary gearbox and gear motor are developed especially for solar energy industry and have served many large-scale solar projects worldwidely.

The research team has more than 15 years experiences in this field, who can ensure a punctual and efficient service to meet customer’s specific needs. It has pasted the ISO9001 quality management system and CE, products have been exported to lots of countries with a wide range application in AGV, intelligent robot, logistic, industrial automation, solar energy, vessel, packaging and textile etc.Consistently, our goal is to promote the application of solar power industry in the world, and we believe it provides clean and sustainable energy for humanity to better protect our environment.

HPS attends 5-6 exhibitions every year, both solar PV exhibitions and automation industry exhibitions, professional sales team and quality products build CZPT a good reputation in the market.

Teams

WORKSHOP

Competitive & Advantages of Planetary Gearbox

* ODM & OEM Service

* Noise Test/ Life Test/ Water-proof Test/ High- Low Temperature Test/ Air-tight Test/ Salt Spray Test

* Low Noise, Low Backlash, High Efficiency

* 20000 Hours Working Life

* 100% Quality Checked with Quality Guaranteed

FAQ

Q1:Which areas are your products mainly used in?

A:At present, we have 2 main products: precision planetary gear reducer and solar geared motor. Most of the precision planetary reducers are used in automation fields, such as medical equipment, 3D printers, door openers, tapping machines, CNC lathes and a series of automation equipment. In addition, our solar geared motors are used in photovoltaic power generation projects, which are mainly combined with rotary drives to drive solar panels to track sunlight.

Q2: How to choose the suitable planetary gearbox?

A :First of all, we need you to be able to provide relevant parameters. If you have a motor drawing, it will let us recommend a suitable gearbox for you faster. If not, we hope you can provide the following motor parameters: output speed, output torque, voltage, current, IP, noise, operating conditions, motor size and power, etc.

Q3: What is the price ?

A : The main determining factor for the price of each product is the order volume. You can communicate with us and let us understand each other. I believe that our prices, product quality and our services can definitely make you satisfied.

Q4: Do you provide customized service?

A: Yes, we provide customized services. You only need to put CZPT your needs, and we will do our best to provide you with a plan, make plans, and try our best to meet your needs.

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Step: | Double-Step |

| Type: | Planetary Gear Reducer |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

The Basics of a Planetary Gearbox

The basic model of a planetary gearbox is a highly efficient transmission that transmits nearly ninety percent of the power it receives. The basic planetary gearbox comes in three basic types: Inline, Helical, and Spur. Below, we will discuss the differences between each of them and which one is better for your needs. A planetary gearbox is an important part of any engine and may be the perfect choice for your vehicle.

Inline planetary gearbox

An inline planetary gearbox has an inline arrangement of gears that enables the transfer of power. Its design makes it stable and reliable, and the space and weight-saving benefits make it a popular choice for many applications. Planetary gearboxes have low inertia, high torque, and a wide range of reduction ratios, which make them a versatile choice for many industries. To find out more about this type of gearbox, read about its construction and specifications.

A planetary gearbox is composed of two parts: a sun gear (also called the central or input gear), and two planet gears (also called outer gears). These gears are connected to each other via a carrier. In order to get the best performance from your gearbox, it’s important to find a model with the features and benefits required for your application. Also, be sure to check out the delivery time, global availability, and customer service of your selected constructor. A few constructors are faster than others and have the ability to respond quickly, while others can deliver every single planetary gearbox out of stock.

Whether you’re using an inline planetary gearbox for your car’s transmission, or you’re building a new machine, it’s important to choose the right size for your application. The most common ratio is five:1, but an inline gearbox can be as high as 1000:1! The torque range is between 250-950 lb-in for continuous torque, and up to 5800 lb-in for yield torque. Some companies even offer custom shafts if you need them to fit a specific application.

Inline planetary gearboxes have a high ratio of helical rotation and are useful for applications where space is limited. Their low-backlash design allows them to handle high torques and high accelerations without backlash. Despite their compact size, planetary gear systems also have high single-stage reduction ratios, a feature that makes them ideal for a variety of industrial applications. They can also be connected for high reduction ratios.

An inline planetary gearbox can be used in many applications, from small tools to heavy industrial machinery. Its basic design includes three components: an input gear pair, an output gear pair, and a stationary position. Some planetary gearbox designs also include additional gear sets that can provide a slight offset between input and output. A planetary gearbox may also contain multiple bearings, which make the assembly more robust and reliable.

Inline planetary gear reducers are commonly used in industrial settings to slow down an electric motor. They are able to multiply torque, which means they can reduce the input speed to a level where the mechanical devices inside the motor can function properly. This type of gear reducer also has a low clearance, which makes it ideal for machines with high torque. However, you should consider the amount of torque required in your application before you make a purchase.

Helical planetary gearbox

A helical planetary gearbox is a type of mechanical system. The gears are connected by joints to the carrier that holds the planets stationary. The sun gear serves as an input to the other gears, and the planet gears rotate at a rate that depends on the number of teeth in each gear. The ratio between these gears is -Ns/Np, and the number of teeth in the ring is N r, N s, and N p.

Another type of planetary gearbox uses multiple helical axes to distribute the load. This design also offers high stiffness and low backlash, which is important for applications involving frequent start-stop cycles and rotational direction changes. It also features a compact design and low mass inertia. A helical planetary gearbox can be used for a wide range of applications. Listed below are some of the benefits of helical gear technology.

The basic design of a helical planetary gear is based on the principle of stepping planets. This concept eliminates the need for timing marks and restrictive assembly conditions. The planetary gear’s helical shape can be modified to achieve a greater transmission ratio in an equal or smaller volume. For example, a 50-T ring gear will yield the same effect as a 100-T ring gear.

In addition to the helical axis, a helical planetary gearbox also has a wide variety of secondary features that are critical to torque transmission. For instance, compact needle roller bearings are appropriate for a helical planetary gearbox because of their low-profile design and small space. However, a tapered roller bearing is better suited to handling high axial forces. In general, a helical planetary gearbox will have a higher efficiency rate and lower noise levels.

A helical planetary gearbox will have a number of components that can vary in size and shape. They will include a sun gear and many planetary parts. The central sun gear will take a low-torque input and will run multiple external gears to increase the torque and speed. This basic model of a planetary gearbox is highly efficient, transferring 97% of the power input. There are three main types of planetary gearboxes: the cylindrical planetary gearbox, the helical planetary gearbox, and the helical wormwheel.

The CZPT is a good example of an entry-level helical planetary gearbox. It is extremely reliable and aimed at providing torque in quiet applications with high precision. The Access series is another option, which is designed to meet the needs of the low-backlash planetary gearbox market. It features helical planetary gears with five to eight arc-minutes backlash, and is built on a monobloc housing.

A helical planetary gearbox is widely used in 3D printing. They are lightweight and can provide a high gear ratio. In addition to their low weight and high efficiency, some people have installed them into 3D printers to improve the accuracy of their designs. And in addition to 3D printing, helical gears are used in many industrial applications. If you’re thinking about purchasing one, you should know what the benefits are.

Spur planetary gearbox

There are many advantages to a spur planetary gearbox, from its compact design and low cost to its unmatched power transmission capacity per unit volume. Planetary gears have high efficiency per stage and can achieve up to 95% efficiency, depending on the ratio. Planet gears are mounted on a joint carrier, and the output rotation speed is slower than the drive rotation speed, which leads to increased torque. The higher the gear wheels, the more torque the unit can produce.

A spur planetary gearbox incorporates multiple other gear sets that must have helical teeth. These other gear sets must be helical, and the motor must be aligned with the driven parts. The spur gears are the most efficient type of planetary gear, as their teeth are symmetrical, which means no axial forces are generated. The difference between a spur and a planetary gearbox is its shape.

The right angle spur planetary gearbox is a versatile design with a spiral bevel gear that provides superior smoothness and quiet operation. This gearhead is case-hardened and ground to increase its efficiency. These gears can be purchased in 3-100 ratios. Spur planetary gearboxes can also have ISO rotary flanges, keyed shafts, DIN splines, or hollow compression connections.

A spur planetary gearbox utilizes spur gears around the circumference of the mechanism. The spur gears rotate between gears that have internal and external teeth. Because of this, the angular velocity of the spur gear differential carrier is the average of the ring gears and sun gears. A spur gearbox can also be considered a compound planetary gear. It is typically used for servo applications. Unlike spur gears, helical planetary gears are easier to maintain and have lower noise levels.

The most notable difference between a spur planetary gearbox and a planetary gearhead is the lubrication of the pinion and the spur gear head. A spur gear head is less complex, but cannot handle the same amount of load as a planetary gearhead. Both types can achieve the same backlash, but a planetary gearhead has better lubrication retention than a spur gear. It can run at higher speeds without excessive lubrication, while a spur gear drive is more efficient at low speeds. The reduction ratio of a planetary gearhead is near unity while that of a planetary gear head is many thousand to one.

A planetary gearbox has many applications. Plastic machinery, goods & personnel lifts, and machine tools are all prime examples of these types of gearing systems. Other industries that use these gears include wind turbines and sugar crystallizers, as well as steel and sugar mills. And of course, the use of planetary gears is not limited to these industries. It is used in many different ways, including slewing drives, mill drive, and derrick & dockyard cranes

editor by CX 2023-10-20

China best Factory Custom Powder Metallurgy Sun Gear for Planetary Gearbox spurs gear

Product Description

Gears produced by powder metallurgy

| Product Name | High precision gear manufacturers by powder metallurgy |

| Material | Iron powder, alloy powder,precious metal powder |

| Technology | Sintering – Powder Metallurgy |

| Certificate | ISO9001/TS16949 |

| Surface Treatment | High frequency quenching, oil impregnation,CNC,vacuum cleaning,polishing, |

| Apperance | No crumbling, cracks, exfoliation, voids, metal pitting and other defects |

| Process Flow |

Powder mixing – Forming – Sintering – Oil impregnation – Sizing -Ultrasonic cleaning – Steam oxidation – Oil impregnation – Final inspection – Packing |

| Application | Motorcycle parts, auto parts, Power Tools parts, Motor parts, electric Bicycle, |

Why Powdered metals?

Significant cost savings.

Create complex or unique shapes.

No or minimal waste during production.

High quality finished products.

Strength of materials

Production process of powder metallurgy

Powder mixing – Forming – Sintering – Oil impregnation – Sizing -Ultrasonic cleaning – Steam oxidation – Oil impregnation – Final inspection – Packing

Company Profile

JINGSHI established in 2007

Manufacturer & Exporter

Exacting in producing powder metallurgy gears and parts

Passed ISO/TS16949 Quality Certificate

Advanced Equipment

Numbers senior R & D engineers and Skilled operators

Precise Examination Instruments.

Strict Quality Control

With the “More diversity, More superior, More professional ” business purposes, we are committed to establish long-term friendship and CHINAMFG relationship with domestic and international customers to create a bright future .

Certification

Please Send us your 2D or 3D drawings to start our cooperation!

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Sintered Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Iron Alloy Powder |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can sun gears be used in automotive applications?

Sun gears are widely used in various automotive applications, playing crucial roles in different systems. Let’s explore the automotive applications where sun gears are commonly employed:

- Automatic Transmissions:

Sun gears are integral components of automatic transmissions in vehicles. Automatic transmissions use planetary gear systems, where the sun gear is one of the key elements. The interaction between the sun gear, planet gears, and ring gear allows for different gear ratios and smooth shifting between gears.

In automatic transmissions, the sun gear is driven by the engine’s input shaft and transmits power to the other gears. By controlling the engagement of various clutches and brakes within the transmission, the sun gear enables seamless gear changes, optimizing vehicle performance and fuel efficiency.

- Transfer Cases:

In four-wheel-drive and all-wheel-drive vehicles, transfer cases distribute power between the front and rear wheels. Sun gears are utilized in transfer cases to facilitate power transfer and gear reduction.

The sun gear, along with other gears and components, helps control the torque distribution and gear ratios between the front and rear axles. This allows vehicles to adapt to different driving conditions, such as slippery surfaces or off-road terrain, enhancing traction and stability.

- Starter Motors:

Sun gears are employed in starter motors, which are responsible for cranking the engine during startup. Starter motors use a gear reduction mechanism to convert the electric motor’s high-speed rotation into a higher torque output.

The sun gear, along with other gears like the planetary gears, enables the gear reduction necessary to generate sufficient torque to crank the engine. This gearing arrangement allows for efficient and reliable engine starting, even in challenging conditions.

- Power Seats and Windows:

Sun gears can also be found in power seat and power window mechanisms in vehicles. These systems use electric motors to adjust seat positions or operate windows.

The sun gear, along with other gears and mechanisms, converts the rotational motion of the electric motor into linear movement, enabling precise adjustments of seat positions or smooth operation of windows. The use of sun gears ensures reliable and efficient functionality of these systems.

- Other Automotive Systems:

Sun gears may also have applications in other automotive systems. For example, they can be found in power steering systems, where they contribute to the gear reduction and power transmission required for smooth steering operation.

Furthermore, sun gears can be utilized in various auxiliary systems, such as cooling fans, HVAC (heating, ventilation, and air conditioning) systems, and engine accessories. These applications leverage the sun gear’s ability to facilitate power transmission and gear reduction, enhancing the efficiency and performance of these systems.

In summary, sun gears are extensively used in automotive applications, including automatic transmissions, transfer cases, starter motors, power seats and windows, power steering systems, and auxiliary systems. Their presence in these systems enables crucial functions such as gear shifting, power distribution, gear reduction, and efficient power transmission. Sun gears contribute to the overall performance, reliability, and functionality of automotive systems, enhancing the driving experience and vehicle efficiency.

What is the role of a sun gear in the operation of a differential gear system?

The sun gear plays a vital role in the operation of a differential gear system, which is commonly used in vehicles to distribute power between the wheels while allowing them to rotate at different speeds. The sun gear, along with other gears in the differential, contributes to the smooth and efficient operation of the system. Here’s an explanation of the role of a sun gear in the operation of a differential gear system:

- Power Input:

The sun gear serves as the input for the differential gear system. It receives torque from the driveshaft or propeller shaft, which transfers power from the engine or transmission to the differential. The rotation of the sun gear initiates the power flow within the differential assembly.

- Speed Differentiation:

The primary function of the differential gear system is to allow the wheels to rotate at different speeds while distributing power between them. The sun gear, along with the other gears in the differential, enables this speed differentiation.

As the sun gear rotates, it meshes with the planet gears, which are arranged around it. The planet gears, in turn, engage with the ring gear, which is connected to the axle shafts leading to the wheels. The interaction between the sun gear, planet gears, and ring gear allows the differential to accommodate different rotational speeds of the wheels.

- Distribution of Torque:

Another critical role of the sun gear is to distribute torque between the wheels in a differential system. The torque input from the sun gear is transmitted to the planet gears, which then transfer the torque to the ring gear and, subsequently, to the axle shafts and wheels.

As the differential operates, it adjusts the distribution of torque based on the traction and resistance encountered by each wheel. If one wheel experiences less resistance or has more traction than the other, the differential will allocate more torque to that wheel. This torque distribution helps optimize power delivery, improve traction, and enhance vehicle stability during cornering or uneven road conditions.

- Equal Torque Split (Open Differential):

In an open differential system, which is the most common type, the sun gear plays a role in equal torque split between the wheels under normal driving conditions. When both wheels have equal traction and resistance, the sun gear distributes torque equally to the planet gears, resulting in an equal torque split between the wheels.

However, in situations where one wheel loses traction or encounters less resistance, such as during wheel slip or when one wheel is on a slippery surface, the open differential will prioritize torque delivery to the wheel with less traction, potentially reducing overall traction and performance.

- Limited-Slip Differential:

In some differential systems, such as limited-slip differentials (LSDs), the sun gear’s role is modified to provide improved traction and torque distribution. LSDs use various mechanisms, such as clutch packs or viscous fluids, to limit the speed differentiation between the wheels and redirect torque to the wheel with more traction.

In LSDs, the sun gear’s engagement with the other gears is modified to allow for controlled torque transfer, enhancing traction and stability during challenging driving conditions.

In summary, the sun gear in a differential gear system serves as the power input and enables speed differentiation and torque distribution between the wheels. Its role is crucial for ensuring smooth power delivery, optimizing traction, and enhancing vehicle stability in various driving conditions.

Can you explain the role of a sun gear in planetary gear systems?

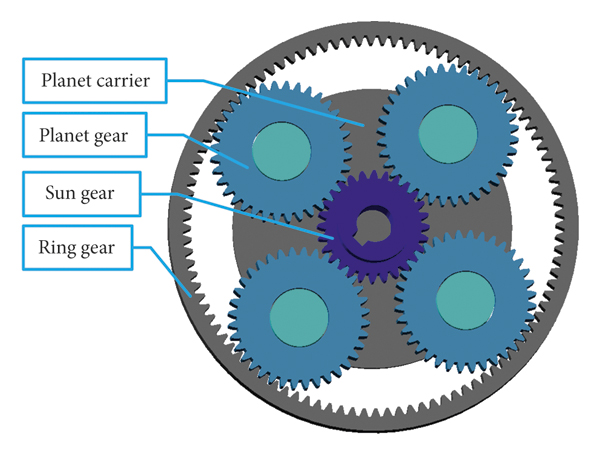

The sun gear plays a crucial role in planetary gear systems, contributing to their unique functionality and versatility. Understanding the specific role of the sun gear within these systems helps in comprehending their overall operation. Here’s an explanation of the role of a sun gear in planetary gear systems:

- Power Input: The sun gear serves as the primary power input element in a planetary gear system. It receives rotational motion and torque from an external source, such as an engine or motor. This power input is transmitted to other gears within the system.

- Engagement with Planet Gears: One of the distinctive features of a planetary gear system is the interaction between the sun gear and multiple planet gears. The planet gears are smaller gears that surround the sun gear and mesh with both the sun gear and an outer ring gear. This engagement allows for the transfer of torque and motion between the gears.

- Power Distribution: As the sun gear rotates, it transmits torque to the planet gears through their meshing teeth. The planet gears, in turn, transfer the torque to the outer ring gear. This power distribution mechanism enables the sharing of torque among multiple gears within the system, allowing for load distribution and efficient power transmission.

- Gear Ratio Control: By changing the arrangement and sizes of the sun gear, planet gears, and ring gear, planetary gear systems can achieve different gear ratios. The number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, determine the gear ratio. This flexibility in gear ratio control enables planetary gear systems to provide various output speeds and torque levels, catering to different operational requirements.

- Torque Amplification: A key advantage of planetary gear systems is their ability to amplify torque. By employing a combination of the sun gear, planet gears, and ring gear, torque can be multiplied or reduced depending on the gear ratio configuration. This torque amplification feature is beneficial in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Directional Control: Another notable aspect of planetary gear systems is their directional control capability. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control adds versatility to gear systems, enabling them to be used in various mechanical applications.

In summary, the sun gear in planetary gear systems serves as the power input element, engages with planet gears, distributes torque, controls gear ratios, provides torque amplification, and enables directional control. Its role is essential in achieving efficient power transmission, versatile gear ratios, and adaptable functionality in a wide range of mechanical applications.

editor by CX 2023-10-20

China Hot selling Pmb6.5 Planetary Gearbox for Mixer Trucks, Pmb7.5 Hydraulic Gearbox for Sales automatic planetary gearbox

Product Description

PMB6.5 Planetary Gearbox For Mixer Trucks, PMB7.5 Hydraulic Gearbox For Sales

The reducer for concrete mixer trucks is used in the transmission system of concrete mixer trucks.

The reducer adopts planetary gear transmission, which has the characteristics of stable torque driving, compact structure, less maintenance and long service life. The reduction gear body can be bolted to the mounting bracket of the frame or directly connected to the frame and connected to the drum through the output flange. The output flange allows for a certain angle of oscillation in all directions to meet the requirements of various complex conditions. This reducer acts as a front support for the drum and drives the drum to rotate through the output flange.

We could supply the CZPT hydraulic pump and motor, also the inner spare parts as below model:

1 A8VO: A8VO55,A8VO80,A8VO107,A8VO160

2,A2FO: A2FO5 A2FO10 A2F12 A2FO16 A2FO23,A2FO28,A2FO32,A2FO45,A2FO56,A2FO63 A2FO80

3,A4VSO: A4VSO40,A4VSO45,A4VSO56,A4VSO71,A4VSO125,A4VSO180,A4VSO250,A4VSO500,

4,A4VG: A4VG28,A4VG45,A4VG50,A4VG56,A4VG71,A4VG125,A4VG180,A4VG250

5,A6V: A6V55,A6V80,A6V107,A6V160,A6V225,A6V250

6,A7V: A7V16,A7V28,A7V55,A7V80,A7V107,A7V160,A7V200,A7V250

7,A8V: A8V55,A8V80,A8V107,A8V115,A8V172

8,A10VSO: A10VSO10,A10VSO18 A10VSO28,A10VSO43,A10VSO45,A10VSO71,A10VSO100,A10VSO140

9,A10VD: A10VD17,A10VD21,A10VD28,A10VD43,A10VD71

10,A11V: A11V50 A11V90 A11V130,A11V145 A11V160,A11V190,A11V250

11,PVV,PV7: PV2.PVV4.PVV5.PVV21.PVV41.PVV42.PVV51.PVV52.PVV54,PV7-1X,PV7-2X

12,PGF,PGH,PGP: GF1-2X,PGF2-2X,PGF3-3X,PGH2-2X,PGH3-2X,PGH4-2X,PGH5-2X,PGP2-2X,PGP3-3X

13 Others: AP2D21,AP2D25,AP2D36,AP2D38

| Usage | Concrete Mixer |

FAQ

Q:What Is Our Main Application?

A:1.Hydraulic system

2.Agriculture machine

3.Construction machina

4.Automobile

5.Local distributors

Q:What Is The Payment Terms?

A:Full order:30% as desposit, the balance before shipment:

Small order /sample ordre: full payment in advance:

Q:Can I Mark My Own Brand On The Pump?

A:Yes. Full order can mark your brand and code.

Q:What Is Our Main Export Market?

A:Europe (41.7%):Italy,Germany,England,France,Holland,Greece,Spain,Portugal,Swissland,Finland,Czekh,Russia,Poland

Asia(40.5%):China,Korea,Singapore,India,Turkey,Iran,Vietnam,Saudi Arabia,Syria,Isreal,Lebanon

| Application: | Agricultural Machinery, Concrete Mixer |

|---|---|

| Function: | Speed Reduction |

| Layout: | Cycloidal |

| Hardness: | Soft Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

What is a Planetary Gearbox?

A planetary gearbox is a mechanical device in which the teeth of a planet mesh with the teeth of its sun or ring. The number of teeth and the spacing of planets will determine whether the teeth mesh correctly. In this article, we will learn more about planetary gearboxes. Besides understanding their working, you can also learn how to design your own. Here are some examples:

planetary gearboxes

If your car has an automatic transmission, then a planetary gearbox is the type you have. It is possible to find out if you have this type of gearbox by consulting the owner’s manual, calling the service department of your car’s manufacturer, or conducting a search using your favorite search engine. However, planetary gears are more complex and have many more components than standard gearboxes. The following information will explain more about this type of gearbox.

Planetary gearboxes use three different gear types to transmit torque. The sun gear sits in the center of the gear assembly, while the other gears rotate around it. A carrier connects the two gears, and is designed to set the spacing between them. When the gears are rotated, the carrier will spin, enabling the entire assembly to work together. The carrier also incorporates the output shaft. For this gearbox to work effectively, it must meet the application’s requirements.

There are three main types of planetary gearboxes: the basic model is highly efficient and transmits 97% of the power input. The earliest models are not complex, but they do have some key differences. Some of these differences make them ideal for various applications. For example, a planetary gearbox can operate in alternating and continuous operation, with the output support having internal grooving. Some designs have more than one output shaft, allowing the user to choose the configuration and torque that is best for their application.

One of the main differences between a planetary gearbox and a conventional one is the way the planetary parts move. A planetary gearbox may have multiple axes for increased torque. A planetary gearbox can provide a torque up to 113,000 N.m. by rotating its maximum teeth simultaneously. They are the ideal choice for space-constrained applications. For instance, a car with small spaces can install one with ease.

A planetary gearbox’s gear ratio is determined by the ratio of the sun gear to the ring gear. The number of teeth on the sun gear is a way to adjust the gear ratio. Smaller sun gears result in larger planetary gear ratios, while larger ones cause a decrease in torque. The ratio between planetary gears ranges from 3:1 to 10:1, with the lowest ratio being three. The greatest possible ratio is 10:1.

A planetary gearbox has many benefits. The compact design makes them a more efficient choice for small motors and is advantageous for servo functions. Planetary gearboxes have low inertia, which is an important factor, especially in servo applications, since the inertia of the gearbox adds to the motor’s load inertia. The planetary gearboxes are typically lubricated with grease or oil, so you don’t need to worry about re-lubrication or maintenance.

planetary gearboxes with output shaft

The advantages of planetary gearboxes are numerous. They are widely used in many applications, from automobiles to medical equipment, goods & personnel lifts to machine tools. They are also used in derrick & dockyard cranes and slewing drives. These gearboxes are available in various sizes and shapes, ranging from small to extremely large. There are many different types, and each is designed to suit its intended use.

The LP generation 3 gearhead series combines maximum quality with economic precision in a low-backlash planetary gearbox. The output shaft version is especially suited for high-speed, highly dynamic cyclic operation. Another version is the SP+ HIGH SPEED. The SP+ high-speed version is designed to achieve maximum speeds while in continuous operation. If you need a planetary gearbox with an output shaft, look no further. It is the best choice for many applications.

As the name suggests, a planetary gearbox incorporates planetary parts and an output shaft. The outer gears (also called the planetary gears) are connected by a carrier to the output shaft. The carrier is then connected to the output shaft by a ring. There are two or more planetary gears inside the planetary gearbox. Each gear is connected to a carrier, which is connected to the output shaft.

An epicyclic planetary gear train can be assembled so that the planet gear rolls around the sun gear. In the wheel drive planetary gearbox, the planetary gears are grouped over the housing to optimize the size and weight of the system. The planetary gear train can handle torques as high as 332,000 N.m., with the ring gear being fixed while the sun gear is movable.

Another advantage of a planetary gearbox is that it uses many teeth at once. This allows for high speed reduction and high torque transmission, and it is extremely compact. Planetary gearboxes with output shaft are ideal for space-constrained applications. Their compact size and minimal weight make them a popular choice in many industries. They are also known as epicyclic gears and are used in many different types of machines.

A planetary gearbox can have three components. A central sun gear, an outer ring known as the inner gear, and an output shaft. These three components are linked by a carrier. The carrier rotates so that the input and output gears are in sync. They also have a standard gap between the gears. The carrier also acts as the output shaft. They can be used to create small machines, such as a bicycle acceleration hub.

planetary gearboxes with integer number of teeth

When designing a planetary gearbox, one must determine the amount of tooth count. This figure is known as the mesh load factor Kg, and is based on the normal tooth forces that are generated in each mesh. The number of planets, the error in the gear design, and the rigidity of the housing all affect Kg. Depending on the type of application, Kg can be calculated by using different standards.

In a typical planetary gearbox, the ratio is an integer number, and the lowest is 3:1. At a ratio of 10, the sun gear is too large and the sun wheel is too low to provide a sufficient amount of torque. In most cases, the ratio is an integer value, and the teeth are evenly spaced. The gear mesh is then balanced to grade 2. The carrier is measured three-dimensionally to detect the accuracy of the planet pin hole in the carrier.

In the simplest case, each planetary gear mesh produces a dynamic signal at its mesh frequency. These signals can cancel or reinforce in various ways. A helix angle, however, introduces axial forces into the gear mesh, which can be cancelled or reinforced in the same way as torques. As the helix angle is an integer number, this planetary gear model does not necessarily require infinite precision.

The resulting motion period is measured in rotational angles. This figure can be used to determine fault diagnosis and calculate the minimum data length required. It can also be used to calculate the kinematic motion of a faulty planet gear tooth. It is important to note that fault-mesh motion is not instantaneous, and therefore, it requires a sufficient amount of time to fully mesh a faulty planet gear.

The load-share factor is similar to that of spur and helical gearboxes, and can be used to calculate dynamic load sharing. When the load share factor is low, the individual gear meshes are slightly loaded. Deflections can vary, especially with high-precision gears. Therefore, the design process should incorporate the tolerance chain. This will ensure the correct ratio of gear mesh.

A planetary gearbox is a type of planetary gear system that is used in motors. It has a sun gear at the center and a set of outer gears. Each gear turns according to its axis around the sun. They are interconnected by a ring component and are connected to each other through a carrier. The carrier also includes the output shaft. And since the sun gear is centered, the mesh is standard.

As an added benefit, planetary gearboxes have sliding surfaces, which reduce noise and vibration. Despite the high-quality of planetary gearboxes, it is important to properly lubricate them to avoid wear and tear. CZPT uses CZPT. In order to make the planetary gearboxes last a long time, the lubricant is usually incorporated in the planetary gearbox.

editor by CX 2023-10-19

China Professional Clg 923D 2ND Planetary Sun Gear Carrier Assy Swing Final Drive Gear for Excavator bevel gearbox

Product Description

Gears for Travel Motor & Swing Motor available:

Planet Carrier Assy,Travel Gear Assembly,Swing Gear Assembly,Ring Gear,Swing Gear,Swing Shaft,Sun Gear, Center Shaft,

Gear Drive/Gear Center,Shaft Pinion,Travel Motor Shaft,Planet Shaft,Planet Gear,RV Gear,Traveling Eccenter Carrier,Eccenter

Shaft,Motor Shaft Gear,Travel Crank Shaft,Travel Motor Casing,Swing/Travel Pinion,Needle Bearing,Ball Bearing,Shaft Pin,HUB,

Flywheel Gear Ring etc..

CLG 923D 2nd Planetary Sun Gear Carrier Assy Swing Final Drive Gear For Excavator

| Part name | Carrier Assy |

| Model | CLG 923D |

| Condition: | brand new |

| Category: | Construction Machinery Parts |

| Installation site: | Excavator Travel Device, Travel Motor |

| Inner Packing: | Wrap by Plastic Film |

| outer packing: | Carton, Plywood Case |

| Delivery: | By Sea, Air, express |

| Delivery time: | Shipped in 5 days after payment |

More Related Products

| 20Y-26-22110 | Gear Sun 1 |

| 20Y-26-22120 | Gear Planetary 1 |

| 20Y-26-22131 | Gear Sun 2 |

| 20Y-26-22141 | Gear Planetary 2 |

| 20Y-26-22240 | Pin Planetary 1 |

| 20Y-26-22250 | Pin Planetary 2 |

| 20Y-27-21280 | Pin Lock Planetary 1 & 2 |

| 20Y-26-21280 | Needle Roller Bearing Planetary 1 |

| 20G-26-11240 | Needle Roller Bearing Planetary 1 |

| 20Y-26-22230 | Plate Thrust Upper Sun Upper |

| 20Y-26-22220 | Plate Thrust Upper Sun Lower |

| 20Y-26-21240 | Plate Thrust Lower Sun |

| 20Y-27-21240 | Plate Thrust Upper / Lower Planetary |

| 20Y-26-21141 | Shaft Propeller |

| 20Y-26-22160 | Carrier Planetary 1 |

| 20Y-26-22170 | Carrier Planetary 2 |

| 20Y-26-22150 | Gear Internal / Ring Gear |

| PC200-6-SD-CA-1 | Carrier Assembly Stage I |

| PC200-6-SD-CA-2 | Carrier Assembly Stage II |

| 04064-5715 | Ring Snap / Ring Retaining |

| 20Y-26-22191 | Cover |

| 20Y-26-22210 | Case / Housing |

| 57110-81045 | Bolt – Cover |

| 57110-62060 | Bolt – Case / Housing |

| 112-32-11211 | Bolt; Shoe – Thrust Plate |

| 01643-31032 | Washer |

| 01643-32060 | Washer |

| 20Y-26-22420 | Seal Oil |

| 20Y-26-22270 | Ring |

| 20Y-26-22330 | Bearing Roller 1 |

| 20Y-26-22340 | Bearing Roller 2 |

| 07000-15240 | O Ring |

| 07000-05240 | O Ring |

More Models

| Motor brand | Motor model |

| NABTESCO | GM02 GM03 GM04 GM05 GM06 GM09 GM18 GM21 GM35 GM60 GM85 GM06VA GM07VC GM08 GM09VN GM10VA GM15 GM17 GM18VL GM20 GM21VA GM23 GM28 GM35VL GM38VB GM40VA GM45VA GM50VA GM60VA GM70VA GM85VA |

| NACHI | PHV-1B PHV-2B PHV-3B PHV-4B PHV80 PHV-120 PHV-190 PHV80 PHV120 PHV190 PHK1B PHK80 PHK100 PHK120 PHK190 |

| KAYABA/KYB | MAG-9N MAG-10V MAG-10VP MAG-16N MAG-16V MAG-18V MAG-18VP MAG-26 MAG-33V MAG-37NV MAG-55KP MAG-85NP MAG-85VP MAG-120P MAG-150VP |

| EATON | JMV016 JMV018 JMV571 JMV571 JMV041 JMV044 JMV047 JMV053 JMV067 JMV076 JMV118 JMV147 JMV168 JMV155 JMV173 JMV185 JMV274 |

| TM SERIES | TM02 TM02E TM03 TM03A TM03CJ TM04 Tm04A Tm04I Tm05 TM06N TM06NK Tm06 TM06K Tm06H Tm06F Tm07 Tm09 TM09E TM09VC Tm18 Tm22 Tm22C TM40A Tm40 |

More Suppliable Travel Motor Assy

| Type | Machine Model | Type | Machine Model |

| GM03 | PC30-7 PC40-7 | E312 | |

| 312B | |||

| GM05V GM06 | PC50UU-1 PC50 | 312C | |

| GM07 | DH55 R60-7 SH60 SY60 | 312D | |

| GM09 TM09 TM10 | PC60-7 PC75UU-1/3 SK60 HD250-7 SH75 SH80 S60 DH80 R80 E307C | 315L | |

| GM18 | PC100-6 PC120-6 PC130-7 PC128UU-1 DH150 R150-7 R160-7 SY150 | 320C | |

| GM35 TM40 | DX225LC DH220-5 S225 EC210B R225-7 R210-3 R210-7 CX160B JMV-147 DX225-7 JY210E | 320D | |

| PC30 PC38UU | 325B | ||

| PC200-3 | 325D 325C | ||

| PC200-6 6D95 | E325L | ||

| PC200-6 6D102 | 330B | ||

| PC200-7 | E330C | ||

| PC210-8 | 307C | ||

| PC220-7 | 308 BSR | ||

| PC228US-2 | 308C | ||

| PC300-6 | 308D | ||

| PC300-7 | 318B | ||

| PC400-6 | E318C | ||

| PC400-7 | GM10Y-B-30-1 | E70B | |

| PC450-7 | EC160B | ||

| EX40 EX50 | EC210 EC210BLC | ||

| EX60-1 | EC240B | ||

| EX75 | EC290BLC | ||

| EX100-1 | EC360 EC360BLC | ||

| EX100-2 | EC460 EC460BLC | ||

| EX200-1 | MAG-26VP-310-2 | ||

| EX200-2 | MAG-33VP-550F-6 | FR60-7 SWE70,6ton excavator | |

| EX200-5 | MAG-33VP-480 | ||

| ZX70 | MAG-33VP-450 | ||

| ZX110 ZX120 | MAG-26VP-320 | ||

| ZX160-1 | MAG85 | ||

| ZX160-3 | MAG-170VP-2400 | ||

| ZX200 | MAG-170VP-3400E-7 | SY215CAI4K SH215-X2 | |

| ZX200-3 | MAG-170VP-3600E-4 LQ15V0000007F2 | SK235, SK230-6 | |

| ZX270 ZX270-3 | MAG170VP-3800G-K1 LQ15V0571F1 | ||

| ZX330 ZX330-3G | MAG-230VP-6000 | ||

| Zx450LC ZX450-3 | MSF-150VP-6-1 | ||

| R140-7 | M4V290-170F LC15V00026F2 M4V290F-RG6.5F LC15V0571F2 | SK350-8 | |

| R290LC-7 | MAG170VP-30 | JS235 | |

| R300-5 | MAG-170VP-5000-7 | HD1430-III | |

| R360-7 | M3V290/170A-RG6 | SH300-3 | |

| SK200LC-1/2/3 | SH450L | ||

| SK200-5 | SH75 | ||

| SK200-6 | JS200 | ||

| SK200-6E | JS240 | ||

| SK200-8 | S220 | ||

| SK220-3 | S230 | ||

| SK250-8 | SY330 | ||

| SK330LC-6E | SY360 | ||

| HMA20BA | UH07-5 UH10LC |

Product Show

More Excavator Spare Parts

| Engine Assembly | Final Drive Assy | Hydraulic Pump | Gear Pump |

| Swing Motor | Travel Motor | Fan Motor | Electrical Parts |

| Swing Gearbox | Travel Gearbox | Relief Valve | Distribution Valve |

| Available Engine Parts | Radiator | Main Valve | Belt |

| Liner Kit | Piston | Piston Ring | Engine Bearing |

| Cylinder Block | Gasket Kit | Gasket Head | Crankshaft |

| Valve | Valve Seat | Valve Xihu (West Lake) Dis. | Nozzle |

| Bearing | Accelerator Motor | Transmitter | Pressure Switch |

| Flameout Solenoid | Monitor | Fan Cooling | Oil Filter |

We could supply the following models

| BRAND | CATALOGUE | ||||||||

| BULLDOZER | D20 | D30 | D31 | D37 | D40 | D41 | D45 | D50 | D60 |

| D65 | D68 | D75 | D80 | D85 | D150 | D155 | D275 | D355 | |

| D3C | D3D | D4C | D4D | D4H | D5 | D6C | D6D | D6H | |

| D7G | D8K | D8N | D9N | D10N | D11N | ||||

| KOMATSU | PC30 | PC40 | PC45 | PC60 | PC75 | PC100 | PC120 | PC150 | PC200 |

| PC220 | PC300 | PC350 | PC400 | ||||||

| CATERPILLAR | E70B | E110 | E120B | E215 | E235 | E307 | E311 | E312 | E322 |

| E180 | E240 | E200B | E320 | E300 | E300B | E330 | E325 | ||

| HITACHI | EX30 | EX40 | EX60 | EX100 | EX120 | EX200 | EX220 | EX270 | EX300 |

| EX400 | EX600 | UH043 | UH052 | UH53 | UH07 | UH081 | UH082 | UH083 | |

| FIAT-HITACHI | FH120 | FH130 | FH150 | FH200 | FH220 | FH270 | FH300 | ||

| VOLVO | EC55 | EC130 | EC150 | EC200 | EC210 | EC240 | EC290 | EC360 | |

| DAEWOO | DH55 | DH130 | DH180 | DH200 | DH280 | DH300 | DH320 | ||

| HYUNDAI | R60 | R130 | R200 | R210 | R220 | R290 | R320 | R914 | |

| KATO | HD250 | HD400 | HD450 | HD700 | HD770 | HD820 | HD1250 | ||

| KOBELCO | SK40 | SK60 | SK100 | SK120 | SK200 | SK220 | SK04-2 | SK07 | |

| SK07N2 | SK09 | SK12 | SK14 | SK300 | SK310 | SK400 | |||

| JCB | JS70 | JS75 | JS110 | JS130 | JS160 | JS180 | JS200 | JS220 | |

| JS240 | JS260 | JS300 | JS330 | ||||||

| SUMITOMO | SH70 | SH100 | SH120 | SH160 | SH200 | SH260 | SH265 | SH280 | SH300 |

| SH340 | LS2650 | LS2800 | LS3400 | LS4300 | |||||

| MX8 | SE200 | SE210 | SE280 | MX292 | SE350 | ||||

| MITSUBISHI | MS110 | MS120 | MS140 | MS180 | |||||

Company Profile

HangZhou Xihu (West Lake) Dis.an Machinery Equipment Co., Ltd

HangZhou Xihu (West Lake) Dis.an Machinery Equipment Co. Ltd. is a professional supplier for hydraulic breaker parts and excavator parts and OEM hydraulic seals manufacturer. We specialize in completed seal kits and separate seals for hydraulic breaker and excavator more than Ten years in HangZhou, China. Koko Shop supply almost all brands breakers’ parts like Seal kits, Diaphragm, Piston, Chisel, Wear Bush upper and lower, Rod Pin, Through Bolts, Side Bolts, Control Valve,Front Head, Cylinder, Accumulator, N2 Gas Charging Kit, etc. We insist on high quality parts with genuine and OEM after market replacement parts.

Specializes in:

–Excavator spare parts

–Hydraulic breaker part

FAQ

Q1.How will you guarantee the quality?

We will test and send testing video to buyer confirm before shipping.

Q2.When will you shiporder?

Once we get cpnfirmation of payment,we will try to our best to ship within 24 hours.

Q3.How long it will take to delivery tomy adress?

The normal delivery time is 5-7 days,depend on which city and transport method.

Q4.How can I track my order?

Once yourorder in shipped,we will e-mail you shipping details.

Q5.If I was not satisfied with the products,can I return goods?

Yes,we offer exchangex and repair service in the warranty time.

| After-sales Service: | on Line |

|---|---|

| Warranty: | 3 Months |

| Type: | Carrier Assy |

| Application: | Excavator |

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

Can you describe the interaction between sun gears and planet gears?

The interaction between sun gears and planet gears is a fundamental aspect of gear systems. Let’s delve into the details of this interaction:

- Planetary Gear Systems:

The interaction between sun gears and planet gears primarily occurs in planetary gear systems. These systems consist of multiple planet gears that rotate around a central sun gear while meshing with an outer ring gear. This arrangement allows for various mechanical advantages and functionalities.

- Power Transmission:

The sun gear serves as the primary driver in a planetary gear system. When power is applied to the sun gear, it transmits rotational force to the planet gears. The planet gears, due to their meshing with both the sun gear and the ring gear, distribute the transmitted power evenly across all the gears.

As the sun gear rotates, the planet gears rotate in the opposite direction around the sun gear while also rotating around their own axes. This rotational movement of the planet gears, driven by the sun gear, plays a crucial role in power transmission within the gear system.

- Speed and Torque Ratios:

The interaction between the sun gear and planet gears affects the speed and torque ratios in a gear system. By choosing different sizes for the sun gear and planet gears, engineers can manipulate the gear ratios to achieve specific outcomes.

When the sun gear is larger than the planet gears, it results in a higher speed ratio. In this case, the sun gear rotates faster than the planet gears, leading to an output shaft or ring gear with increased rotational speed relative to the input shaft or sun gear.

Conversely, when the sun gear is smaller than the planet gears, it leads to a lower speed ratio. In this scenario, the sun gear rotates slower than the planet gears, resulting in an output shaft or ring gear with reduced rotational speed compared to the input shaft or sun gear.

Similarly, the interaction between the sun gear and planet gears affects the torque ratio. When the sun gear is larger than the planet gears, it amplifies the torque, resulting in higher output torque relative to the input torque. Conversely, when the sun gear is smaller, it reduces the torque, resulting in lower output torque compared to the input torque.

- Direction Reversal:

The interaction between the sun gear and planet gears also enables torque direction reversal in planetary gear systems. When the sun gear rotates in a specific direction, it imparts torque to the planet gears, causing them to rotate in the opposite direction around the sun gear.

This counterclockwise rotation of the planet gears, as driven by the sun gear, leads to the ring gear rotating in the opposite direction. By reversing the direction of the sun gear’s rotation, the torque direction can be reversed once again. This ability to change torque direction makes planetary gear systems versatile and applicable in various mechanical and automotive applications.

- Mechanical Advantages:

The interaction between sun gears and planet gears offers several mechanical advantages. The distribution of torque across multiple planet gears allows for increased load-bearing capacity and improved system reliability. As each planet gear shares the load, the overall stress on individual gears is reduced, enhancing the system’s durability.

Moreover, the arrangement of sun gears and planet gears in a planetary gear system results in compact designs and high power density. The distributed power transmission and torque-sharing characteristics enable the system to handle higher loads while occupying minimal space.

In summary, the interaction between sun gears and planet gears in planetary gear systems is crucial for power transmission, achieving speed and torque ratios, enabling torque direction reversal, and providing mechanical advantages such as load distribution and compact designs. Understanding this interaction is essential for designing and optimizing gear systems in various applications.

How do you calculate gear ratios involving a sun gear in planetary systems?

Calculating gear ratios in planetary systems involving a sun gear requires considering the number of teeth on the gears and their arrangement. Understanding the calculation process helps in determining the gear ratio and predicting the rotational relationship between the input and output gears. Here’s an explanation of how to calculate gear ratios involving a sun gear in planetary systems:

- Step 1: Identify the Gears: In a planetary system, identify the gears involved, namely the sun gear, planet gears, and ring gear. The sun gear is the gear at the center, surrounded by the planet gears, which in turn engage with the outer ring gear.

- Step 2: Count the Teeth: Count the number of teeth on each gear. The sun gear, planet gears, and ring gear all have a specific number of teeth. Let’s denote these as Ts (sun gear teeth), Tp (planet gear teeth), and Tr (ring gear teeth).

- Step 3: Determine the Gear Ratio: The gear ratio in a planetary system involving a sun gear is calculated using the following formula:

Gear Ratio = (Tp + Tr) / Ts

- Step 4: Interpret the Gear Ratio: The calculated gear ratio represents the rotational relationship between the input (sun gear) and output (ring gear) gears. For example, if the gear ratio is 2:1, it means that for every two revolutions of the sun gear, the ring gear completes one revolution in the opposite direction.

- Step 5: Adjust for Multiple Planet Gears or Fixed Components: In some cases, planetary systems may involve multiple planet gears or fixed components. The presence of multiple planet gears affects the gear ratio, and the inclusion of fixed components alters the gear engagement and behavior. These factors may require additional calculations or adjustments to accurately determine the gear ratio.

In summary, calculating gear ratios involving a sun gear in planetary systems necessitates identifying the gears, counting the teeth on each gear, and applying the appropriate formula. The resulting gear ratio provides insights into the rotational relationship between the sun gear and the ring gear. It’s important to consider any additional elements, such as multiple planet gears or fixed components, that may influence the gear ratio calculation.

What is the purpose of using a sun gear in mechanical applications?

The use of a sun gear in mechanical applications serves several important purposes. This central gear component plays a crucial role in achieving specific functionalities and benefits within gear systems. Here’s an explanation of the purpose of using a sun gear:

- Power Transmission: The primary purpose of a sun gear is to facilitate power transmission within gear systems. It acts as a central driver that receives power input, typically from an external source such as an engine or motor. The sun gear transfers torque to other gears, enabling the transmission of rotational motion and power throughout the system.

- Gear Ratio Control: Sun gears are instrumental in controlling the gear ratio within a gear system. By altering the size, number of teeth, and interaction with other gears such as planet gears and ring gears, the sun gear helps determine the overall gear ratio. This allows for the adjustment of rotational speed and torque output according to the specific requirements of the mechanical application.

- Torque Multiplication: In certain gear systems, a sun gear can be used to multiply torque. By employing a planetary gear arrangement, where the sun gear interacts with multiple planet gears and an outer ring gear, torque can be amplified. This torque multiplication capability of the sun gear is particularly useful in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Directional Control: Sun gears can also play a role in controlling the direction of power transmission within gear systems. In planetary gear arrangements, fixing or holding the sun gear while the ring gear or planet carrier is driven can result in different output directions, such as forward or reverse rotation. This directional control feature adds versatility to gear systems, allowing them to be utilized in various mechanical applications.

- Compact Design: The utilization of a sun gear in gear systems often enables a more compact and space-efficient design. The central positioning of the sun gear, along with the arrangement of other gears, allows for a reduction in overall size while maintaining efficient power transmission. This compactness is advantageous in applications with limited space or weight restrictions.

In summary, the purpose of using a sun gear in mechanical applications is to facilitate power transmission, control gear ratios, provide torque multiplication, offer directional control, and enable compact designs. The specific application and requirements of a mechanical system determine the selection and utilization of sun gears, ensuring efficient and reliable operation in various industries such as automotive, aerospace, industrial machinery, and more.

editor by CX 2023-10-19

China OEM 22mm DC 24V 26rpm Low Speed Low Power Micro Planetary Gearbox small planetary gearbox

Product Description

DC 24V 26rpm Low speed Low Power Micro Planetary Gearbox

Product Description

Model: ZWMD571571-256

- Rated Voltage: 24v

- No Load Speed: 28 rpm

- No Load Current: 120mA

- Rated Load Speed: 26rpm

- Rated Load Current: 300 mA

- Rated Load Torque: 4050 gf.cm

- Rated Torque of Gear Box: 5000 gf.cm

- Instant Torque of Gear Box: 10000 gf.cm

- Overall Length L: 71.7 mm

- Gear Box Length L1: 33.4 mm

We also have the following items:

| Model | Application Parameters | Rated Torque of Gear Box |

Instant Torque of Gear Box |

Gear Ratio |

Gear Box Length L1 |

|||||||

| Rated |

At No Load |

At Rated Load | Overall Length L |

|||||||||

| Voltage |

Speed |

Current |

Speed |

Current |

Torque |

|||||||

| VDC | rpm | mA | rpm | mA | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| ZWMD571571-4 | 24.0 | 1886 | 100 | 1675 | 295 | 160 | 15.7 | 56.4 | 800 | 2400 | 4 | 18.1 |

| ZWMD571571-5 | 24.0 | 1509 | 100 | 1340 | 295 | 200 | 19.6 | 800 | 2400 | 5 | ||

| ZWMD571571-16 | 24.0 | 472 | 110 | 419 | 295 | 512 | 50.2 | 61.5 | 2000 | 6000 | 16 | 23.2 |

| ZWMD571571-19 | 24.0 | 397 | 110 | 353 | 295 | 608 | 59.6 | 2000 | 6000 | 19 | ||

| ZWMD571571-23 | 24.0 | 328 | 110 | 291 | 295 | 736 | 72.2 | 2000 | 6000 | 23 | ||

| ZWMD571571-64 | 24.0 | 118 | 120 | 105 | 295 | 1350 | 132.4 | 66.6 | 3500 | 10000 | 64 | 28.3 |

| ZWMD571571-76 | 24.0 | 99 | 120 | 88 | 295 | 1603 | 157.2 | 3500 | 10000 | 76 | ||

| ZWMD571571-90 | 24.0 | 84 | 120 | 74 | 295 | 1898 | 186.2 | 3500 | 10000 | 90 | ||

| ZWMD571571-107 | 24.0 | 71 | 120 | 63 | 295 | 2257 | 221.3 | 3500 | 10000 | 107 | ||

| ZWMD571571-256 | 24.0 | 28 | 120 | 26 | 300 | 4050 | 397.2 | 71.7 | 5000 | 10000 | 256 | 33.4 |

| ZWMD571571-304 | 24.0 | 24 | 120 | 22 | 300 | 4809 | 472 | 5000 | 10000 | 304 | ||

| ZWMD571571-361 | 24.0 | 20 | 120 | 19 | 300 | 5000 | 490 | 5000 | 10000 | 361 | ||

| ZWMD571571-429 | 24.0 | 17 | 120 | 16 | 300 | 5000 | 490 | 5000 | 10000 | 429 | ||

| ZWMD571571-509 | 24.0 | 14 | 120 | 13 | 300 | 3500 | 343 | 3500 | 10000 | 509 | ||

above specifications just for reference and customizable according to requirements.

Can be Integrated Drive Control Module.

Please let us know your requirements and we will provide you with micro transmission solutions.

2D Drawing:

Detailed Photos

Application

| Smart wearable devices | watch,VR,AR,XR and etc. |

| Household application | kitchen appliances, sewing machines, corn popper, vacuum cleaner, garden tool, sanitary ware, window curtain, intelligent closestool, sweeping robot, power seat, standing desk, electric sofa, TV, computer, treadmill, spyhole, cooker hood, electric drawer, electric mosquito net, intelligent cupboard, intelligent wardrobe, automatic soap dispenser, UV baby bottle sterilizer, lifting hot pot cookware, dishwasher, washing machine, food breaking machine, dryer, air conditioning, dustbin, coffee machine, whisk,smart lock,bread maker,Window cleaning robot and etc. |

| communication equipment | 5G base station,video conference,mobile phone and etc. |

| Office automation equipments | scanners, printers, multifunction machines copy machines, fax (FAX paper cutter), computer peripheral, bank machine, screen, lifting socket, display,notebook PC and etc. |

| Automotive products | conditioning damper actuator, car DVD,door lock actuator, retractable rearview mirror, meters, optic axis control device, head light beam level adjuster, car water pump, car antenna, lumbar support, EPB, car tail gate electric putter, HUD, head-up display, vehicle sunroof, EPS, AGS, car window, head restraint, E-booster, car seat, vehicle charging station and etc. |

| Toys and models | radio control model, automatic cruise control, ride-on toy, educational robot, programming robot, medical robot, automatic feeder, intelligent building blocks, escort robot and etc. |

| Medical equipments | blood pressure meter, breath machine, medical cleaning pump, medical bed, blood pressure monitors, medical ventilator, surgical staplers, infusion pump, dental instrument, self-clotting cutter, wound cleaning pump for orthopedic surgery,electronic cigarette, eyebrow pencil,fascia gun, , surgical robot,laboratory automation and etc. |

| Industrials | flow control valves, seismic testing,automatic reclosing,Agricultural unmanned aerial vehicle,automatic feeder ,intelligent express cabinet and etc. |

| Electric power tools | electric drill, screwdriver,garden tool and etc. |

| Precision instruments | optics instruments,automatic vending machine, wire-stripping machine and etc. |

| Personal care | tooth brush, hair clipper, electric shaver, massager, vibrator, hair dryer, rubdown machine, scissor hair machine, foot grinder,anti-myopia pen, facial beauty equipment, hair curler,Electric threading knife,POWER PERFECT PORE, Puff machine,eyebrow tweezers and etc. |

| Consumer electronics | camera, mobile phone,digital camera, automatic retracting device,camcorder, kinescope DVD,headphone stereo, cassette tape recorder, bluetooth earbud charging case, turntable, tablet,UAV(unmanned aerial vehicle),surveillance camera,PTZ camera, rotating smart speaker and etc. |

| robots | educational robot, programming robot, medical robot, escort robot and etc. |

Company Profile

HangZhou CZPT Machinery & Electronics Co., Ltd was established in 2001,We provide the total drive solution for customers from design, tooling fabrication, components manufacturing and assembly.

Workshop

Testing Equipment

1) Competitive Advantages

- 1) Competitive Advantages

19+year experience in manufacturing motor gearbox

We provide technical support from r&d, prototype, testing, assembly and serial production , ODM &OEM

Competitive Price

Product Performance: Low noise, High efficiency, Long lifespan

Prompt Delivery: 15 working days after payment

Small Orders Accepted

2) Main Products

-

Precision reduction gearbox and its diameter:3.4mm-38mm,voltage:1.5-24V,power: 0.01-40W,output speed:5-2000rpm and output torque:1.0 gf.cm -50kgf.cm,

- Customized worm and gear transmission machinery;

- Precise electromechanical motion module;

- Precise component and assembly of plastic and metal powder injection.

Our Services

- ODM & OEM

- Gearbox design and development

- Related technology support

- Micro drive gearbox custom solution

Packaging & Shipping

1) Packing Details

packed in nylon firstly, then carton, and then reinforced with wooden case for outer packing.

Or according to client’s requirement.

2) Shipping Details

samples will be shipped within 10 days;

batch order leading time according to the actual situation.

Certifications

Certifications

We Have passed to hold ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and more…

FAQ

FAQ

1. Can you make the gearbox with custom specifications?

YES. We have design and development team, also a great term of engineers, each of them have

many work years experience.

2.Do you provide the samples?

YES. Our company can provide the samples to you, and the delivery time is about 5-15days according to the specification of gearbox you need.

3.What is your MOQ?

Our MOQ is 2000pcs. But at the beginning of our business, we accept small order.

4. Do you have the item in stock?

I am sorry we donot have the item in stock, All products are made with orders.

5. Do you provide technology support?

YES. Our company have design and development team, we can provide technology support if you

need.

6.How to ship to us?

We will ship the goods to you according to the DHL or UPS or FEDEX etc account you provide.

7.How to pay the money?

We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

8. How can I know the product is suitable for me?

Frist, you need to provide us the more details information about the product. We will recommend the item to you according to your requirement of specification. After you confirm, we will prepare the samples to you. also we will offer some good advances according to your product use.

9. Can I come to your company to visit?

YES, you can come to our company to visit at anytime, and welcome to visit our company.

10. How do contact us ?

Please send an inquiry

| Application: | Motor, Toy, Car |

|---|---|

| Function: | Change Drive Torque, Speed Reduction |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Customize |

| Step: | Customize |

| Samples: |

US$ 80/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Planetary Gearbox Advantages and Disadvantages

A planetary gearbox is a type of mechanical drive with a single output shaft. They are suitable for both clockwise and counterclockwise rotations, have less inertia, and operate at higher speeds. Here are some advantages and disadvantages of this type of gearbox. Let us see what these advantages are and why you should use them in your applications. Listed below are some of the benefits of planetary gearboxes.

Suitable for counterclockwise and clockwise rotation

If you want to teach children about the clock hands, you can buy some resources for counterclockwise and asymmetrical rotation. These resources include worksheets for identifying degrees of rotation, writing rules for rotation, and visual processing. You can also use these resources to teach angles. For example, the translation of shapes activity pack helps children learn about the rotation of geometric shapes. Similarly, the visual perception activity sheet helps children understand how to process information visually.

Various studies have been done to understand the anatomical substrate of rotations. In a recent study, CZPT et al. compared the position of the transitional zone electrocardiographically and anatomically. The authors found that the transitional zone was normal in nine of 33 subjects, indicating that rotation is not a sign of disease. Similarly, a counterclockwise rotation may be caused by a genetic or environmental factor.

The core tip data should be designed to work in both clockwise and counterclockwise rotation. Counterclockwise rotation requires a different starting point than a clockwise rotation. In North America, star-delta starting is used. In both cases, the figure is rotated about its point. Counterclockwise rotation, on the other hand, is done in the opposite direction. In addition, it is possible to create counterclockwise rotation using the same gimbal.