Product Description

Gears for Travel Motor & Swing Motor available:

Planet Carrier Assy,Travel Gear Assembly,Swing Gear Assembly,Ring Gear,Swing Gear,Swing Shaft,Sun Gear, Center Shaft,

Gear Drive/Gear Center,Shaft Pinion,Travel Motor Shaft,Planet Shaft,Planet Gear,RV Gear,Traveling Eccenter Carrier,Eccenter

Shaft,Motor Shaft Gear,Travel Crank Shaft,Travel Motor Casing,Swing/Travel Pinion,Needle Bearing,Ball Bearing,Shaft Pin,HUB,

Flywheel Gear Ring etc..

CLG 923D 2nd Planetary Sun Gear Carrier Assy Swing Final Drive Gear For Excavator

| Part name | Carrier Assy |

| Model | CLG 923D |

| Condition: | brand new |

| Category: | Construction Machinery Parts |

| Installation site: | Excavator Travel Device, Travel Motor |

| Inner Packing: | Wrap by Plastic Film |

| outer packing: | Carton, Plywood Case |

| Delivery: | By Sea, Air, express |

| Delivery time: | Shipped in 5 days after payment |

More Related Products

| 20Y-26-22110 | Gear Sun 1 |

| 20Y-26-22120 | Gear Planetary 1 |

| 20Y-26-22131 | Gear Sun 2 |

| 20Y-26-22141 | Gear Planetary 2 |

| 20Y-26-22240 | Pin Planetary 1 |

| 20Y-26-22250 | Pin Planetary 2 |

| 20Y-27-21280 | Pin Lock Planetary 1 & 2 |

| 20Y-26-21280 | Needle Roller Bearing Planetary 1 |

| 20G-26-11240 | Needle Roller Bearing Planetary 1 |

| 20Y-26-22230 | Plate Thrust Upper Sun Upper |

| 20Y-26-22220 | Plate Thrust Upper Sun Lower |

| 20Y-26-21240 | Plate Thrust Lower Sun |

| 20Y-27-21240 | Plate Thrust Upper / Lower Planetary |

| 20Y-26-21141 | Shaft Propeller |

| 20Y-26-22160 | Carrier Planetary 1 |

| 20Y-26-22170 | Carrier Planetary 2 |

| 20Y-26-22150 | Gear Internal / Ring Gear |

| PC200-6-SD-CA-1 | Carrier Assembly Stage I |

| PC200-6-SD-CA-2 | Carrier Assembly Stage II |

| 04064-5715 | Ring Snap / Ring Retaining |

| 20Y-26-22191 | Cover |

| 20Y-26-22210 | Case / Housing |

| 57110-81045 | Bolt – Cover |

| 57110-62060 | Bolt – Case / Housing |

| 112-32-11211 | Bolt; Shoe – Thrust Plate |

| 01643-31032 | Washer |

| 01643-32060 | Washer |

| 20Y-26-22420 | Seal Oil |

| 20Y-26-22270 | Ring |

| 20Y-26-22330 | Bearing Roller 1 |

| 20Y-26-22340 | Bearing Roller 2 |

| 07000-15240 | O Ring |

| 07000-05240 | O Ring |

More Models

| Motor brand | Motor model |

| NABTESCO | GM02 GM03 GM04 GM05 GM06 GM09 GM18 GM21 GM35 GM60 GM85 GM06VA GM07VC GM08 GM09VN GM10VA GM15 GM17 GM18VL GM20 GM21VA GM23 GM28 GM35VL GM38VB GM40VA GM45VA GM50VA GM60VA GM70VA GM85VA |

| NACHI | PHV-1B PHV-2B PHV-3B PHV-4B PHV80 PHV-120 PHV-190 PHV80 PHV120 PHV190 PHK1B PHK80 PHK100 PHK120 PHK190 |

| KAYABA/KYB | MAG-9N MAG-10V MAG-10VP MAG-16N MAG-16V MAG-18V MAG-18VP MAG-26 MAG-33V MAG-37NV MAG-55KP MAG-85NP MAG-85VP MAG-120P MAG-150VP |

| EATON | JMV016 JMV018 JMV571 JMV571 JMV041 JMV044 JMV047 JMV053 JMV067 JMV076 JMV118 JMV147 JMV168 JMV155 JMV173 JMV185 JMV274 |

| TM SERIES | TM02 TM02E TM03 TM03A TM03CJ TM04 Tm04A Tm04I Tm05 TM06N TM06NK Tm06 TM06K Tm06H Tm06F Tm07 Tm09 TM09E TM09VC Tm18 Tm22 Tm22C TM40A Tm40 |

More Suppliable Travel Motor Assy

| Type | Machine Model | Type | Machine Model |

| GM03 | PC30-7 PC40-7 | E312 | |

| 312B | |||

| GM05V GM06 | PC50UU-1 PC50 | 312C | |

| GM07 | DH55 R60-7 SH60 SY60 | 312D | |

| GM09 TM09 TM10 | PC60-7 PC75UU-1/3 SK60 HD250-7 SH75 SH80 S60 DH80 R80 E307C | 315L | |

| GM18 | PC100-6 PC120-6 PC130-7 PC128UU-1 DH150 R150-7 R160-7 SY150 | 320C | |

| GM35 TM40 | DX225LC DH220-5 S225 EC210B R225-7 R210-3 R210-7 CX160B JMV-147 DX225-7 JY210E | 320D | |

| PC30 PC38UU | 325B | ||

| PC200-3 | 325D 325C | ||

| PC200-6 6D95 | E325L | ||

| PC200-6 6D102 | 330B | ||

| PC200-7 | E330C | ||

| PC210-8 | 307C | ||

| PC220-7 | 308 BSR | ||

| PC228US-2 | 308C | ||

| PC300-6 | 308D | ||

| PC300-7 | 318B | ||

| PC400-6 | E318C | ||

| PC400-7 | GM10Y-B-30-1 | E70B | |

| PC450-7 | EC160B | ||

| EX40 EX50 | EC210 EC210BLC | ||

| EX60-1 | EC240B | ||

| EX75 | EC290BLC | ||

| EX100-1 | EC360 EC360BLC | ||

| EX100-2 | EC460 EC460BLC | ||

| EX200-1 | MAG-26VP-310-2 | ||

| EX200-2 | MAG-33VP-550F-6 | FR60-7 SWE70,6ton excavator | |

| EX200-5 | MAG-33VP-480 | ||

| ZX70 | MAG-33VP-450 | ||

| ZX110 ZX120 | MAG-26VP-320 | ||

| ZX160-1 | MAG85 | ||

| ZX160-3 | MAG-170VP-2400 | ||

| ZX200 | MAG-170VP-3400E-7 | SY215CAI4K SH215-X2 | |

| ZX200-3 | MAG-170VP-3600E-4 LQ15V0000007F2 | SK235, SK230-6 | |

| ZX270 ZX270-3 | MAG170VP-3800G-K1 LQ15V0571F1 | ||

| ZX330 ZX330-3G | MAG-230VP-6000 | ||

| Zx450LC ZX450-3 | MSF-150VP-6-1 | ||

| R140-7 | M4V290-170F LC15V00026F2 M4V290F-RG6.5F LC15V0571F2 | SK350-8 | |

| R290LC-7 | MAG170VP-30 | JS235 | |

| R300-5 | MAG-170VP-5000-7 | HD1430-III | |

| R360-7 | M3V290/170A-RG6 | SH300-3 | |

| SK200LC-1/2/3 | SH450L | ||

| SK200-5 | SH75 | ||

| SK200-6 | JS200 | ||

| SK200-6E | JS240 | ||

| SK200-8 | S220 | ||

| SK220-3 | S230 | ||

| SK250-8 | SY330 | ||

| SK330LC-6E | SY360 | ||

| HMA20BA | UH07-5 UH10LC |

Product Show

More Excavator Spare Parts

| Engine Assembly | Final Drive Assy | Hydraulic Pump | Gear Pump |

| Swing Motor | Travel Motor | Fan Motor | Electrical Parts |

| Swing Gearbox | Travel Gearbox | Relief Valve | Distribution Valve |

| Available Engine Parts | Radiator | Main Valve | Belt |

| Liner Kit | Piston | Piston Ring | Engine Bearing |

| Cylinder Block | Gasket Kit | Gasket Head | Crankshaft |

| Valve | Valve Seat | Valve Xihu (West Lake) Dis. | Nozzle |

| Bearing | Accelerator Motor | Transmitter | Pressure Switch |

| Flameout Solenoid | Monitor | Fan Cooling | Oil Filter |

We could supply the following models

| BRAND | CATALOGUE | ||||||||

| BULLDOZER | D20 | D30 | D31 | D37 | D40 | D41 | D45 | D50 | D60 |

| D65 | D68 | D75 | D80 | D85 | D150 | D155 | D275 | D355 | |

| D3C | D3D | D4C | D4D | D4H | D5 | D6C | D6D | D6H | |

| D7G | D8K | D8N | D9N | D10N | D11N | ||||

| KOMATSU | PC30 | PC40 | PC45 | PC60 | PC75 | PC100 | PC120 | PC150 | PC200 |

| PC220 | PC300 | PC350 | PC400 | ||||||

| CATERPILLAR | E70B | E110 | E120B | E215 | E235 | E307 | E311 | E312 | E322 |

| E180 | E240 | E200B | E320 | E300 | E300B | E330 | E325 | ||

| HITACHI | EX30 | EX40 | EX60 | EX100 | EX120 | EX200 | EX220 | EX270 | EX300 |

| EX400 | EX600 | UH043 | UH052 | UH53 | UH07 | UH081 | UH082 | UH083 | |

| FIAT-HITACHI | FH120 | FH130 | FH150 | FH200 | FH220 | FH270 | FH300 | ||

| VOLVO | EC55 | EC130 | EC150 | EC200 | EC210 | EC240 | EC290 | EC360 | |

| DAEWOO | DH55 | DH130 | DH180 | DH200 | DH280 | DH300 | DH320 | ||

| HYUNDAI | R60 | R130 | R200 | R210 | R220 | R290 | R320 | R914 | |

| KATO | HD250 | HD400 | HD450 | HD700 | HD770 | HD820 | HD1250 | ||

| KOBELCO | SK40 | SK60 | SK100 | SK120 | SK200 | SK220 | SK04-2 | SK07 | |

| SK07N2 | SK09 | SK12 | SK14 | SK300 | SK310 | SK400 | |||

| JCB | JS70 | JS75 | JS110 | JS130 | JS160 | JS180 | JS200 | JS220 | |

| JS240 | JS260 | JS300 | JS330 | ||||||

| SUMITOMO | SH70 | SH100 | SH120 | SH160 | SH200 | SH260 | SH265 | SH280 | SH300 |

| SH340 | LS2650 | LS2800 | LS3400 | LS4300 | |||||

| MX8 | SE200 | SE210 | SE280 | MX292 | SE350 | ||||

| MITSUBISHI | MS110 | MS120 | MS140 | MS180 | |||||

Company Profile

HangZhou Xihu (West Lake) Dis.an Machinery Equipment Co., Ltd

HangZhou Xihu (West Lake) Dis.an Machinery Equipment Co. Ltd. is a professional supplier for hydraulic breaker parts and excavator parts and OEM hydraulic seals manufacturer. We specialize in completed seal kits and separate seals for hydraulic breaker and excavator more than Ten years in HangZhou, China. Koko Shop supply almost all brands breakers’ parts like Seal kits, Diaphragm, Piston, Chisel, Wear Bush upper and lower, Rod Pin, Through Bolts, Side Bolts, Control Valve,Front Head, Cylinder, Accumulator, N2 Gas Charging Kit, etc. We insist on high quality parts with genuine and OEM after market replacement parts.

Specializes in:

–Excavator spare parts

–Hydraulic breaker part

FAQ

Q1.How will you guarantee the quality?

We will test and send testing video to buyer confirm before shipping.

Q2.When will you shiporder?

Once we get cpnfirmation of payment,we will try to our best to ship within 24 hours.

Q3.How long it will take to delivery tomy adress?

The normal delivery time is 5-7 days,depend on which city and transport method.

Q4.How can I track my order?

Once yourorder in shipped,we will e-mail you shipping details.

Q5.If I was not satisfied with the products,can I return goods?

Yes,we offer exchangex and repair service in the warranty time.

| After-sales Service: | on Line |

|---|---|

| Warranty: | 3 Months |

| Type: | Carrier Assy |

| Application: | Excavator |

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

How does a sun gear contribute to changes in torque direction in gear systems?

A sun gear plays a crucial role in gear systems when it comes to changing the direction of torque. Let’s delve into the details of how a sun gear contributes to torque direction changes in gear systems:

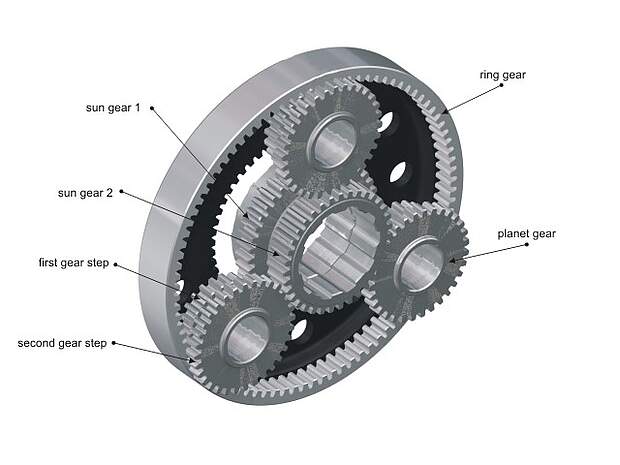

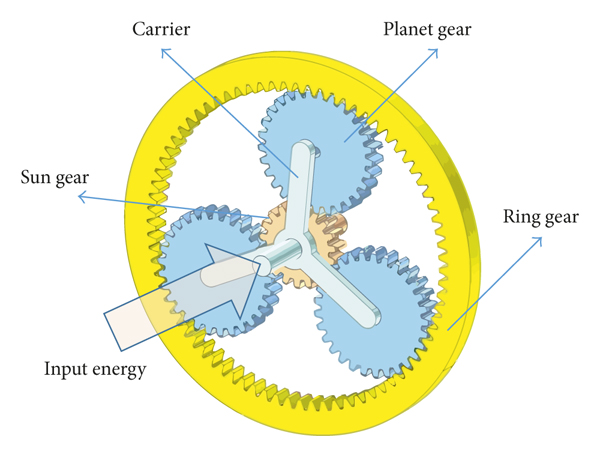

- Planetary Gear Systems:

In planetary gear systems, the sun gear is one of the primary components along with the planet gears and the ring gear. These systems consist of one or more planet gears that mesh with both the sun gear and the ring gear. The arrangement of these gears allows for various torque direction changes.

- Torque Transmission:

The sun gear acts as a central driver in a planetary gear system. As power is applied to the sun gear, it transmits torque to the planet gears. The planet gears, in turn, engage with the ring gear, which ultimately transfers the torque to the output shaft or the desired component.

When the sun gear rotates in a specific direction, it imparts torque to the planet gears. The planet gears, due to their meshing with the stationary ring gear, distribute the torque evenly across all the gears. This torque transmission mechanism allows for the transfer of rotational force from the input (sun gear) to the output (ring gear or output shaft) of the system.

- Direction Reversal:

The unique configuration of a planetary gear system allows for torque direction changes. By manipulating the relative sizes and arrangements of the gears, including the sun gear, it is possible to reverse the direction of the torque output.

For instance, when the sun gear serves as the input and rotates clockwise, it causes the planet gears to rotate counterclockwise. This counterclockwise rotation, in turn, causes the ring gear to rotate in the clockwise direction, resulting in a torque reversal.

Similarly, by reversing the direction of the sun gear’s rotation, the torque direction can be reversed once again. This ability to change the torque direction makes planetary gear systems versatile and applicable in various mechanical and automotive applications.

- Torque Amplification and Reduction:

Another way the sun gear contributes to torque direction changes is through torque amplification and reduction. By incorporating different gear ratios within the planetary gear system, it is possible to alter the torque output relative to the input.

A specific arrangement of gear sizes, including the sun gear, can result in torque amplification. Torque amplification occurs when the output torque is greater than the input torque. This configuration can be beneficial in applications where increased torque is required, such as in heavy machinery or vehicles.

Conversely, torque reduction can be achieved by utilizing different gear ratios. By adjusting the sizes of the gears, including the sun gear, the output torque can be lower than the input torque. Torque reduction is useful in situations where precision control or lower torque output is necessary, such as in robotics or delicate machinery.

- Overall Torque Control:

The sun gear’s contribution to torque direction changes in gear systems provides a means of overall torque control. By manipulating the rotation direction and gear ratios, the torque can be directed, amplified, or reduced according to the specific requirements of the application.

Engineers and designers can utilize the sun gear, along with other gears in the system, to achieve the desired torque direction, torque amplification or reduction, and mechanical power transmission within gear systems.

In conclusion, the sun gear is a critical component in gear systems for changing torque direction. It enables torque transmission, facilitates torque direction reversal, contributes to torque amplification or reduction, and provides overall torque control within planetary gear systems and other similar gear configurations.

Can you explain the function of a sun gear in automatic transmissions?

The sun gear plays a crucial role in the operation of automatic transmissions. It is an essential component within the planetary gear set, which is responsible for transmitting power and controlling gear ratios in automatic transmissions. Here’s an explanation of the function of a sun gear in automatic transmissions:

- Power Input:

The sun gear serves as one of the primary power input sources in an automatic transmission. It connects to the torque converter, which is a fluid coupling that transfers engine power to the transmission. The rotation of the sun gear receives torque from the engine and acts as the initial input for the gear set.

- Gear Ratio Control:

The sun gear, along with other gears in the planetary gear set, allows for the control of gear ratios in an automatic transmission. By varying the engagement and rotation of the sun gear, different gear ratios can be achieved, providing the desired combination of torque multiplication and speed reduction or increase.

The gear ratio control is achieved through the interaction between the sun gear, planet gears, and ring gear. The sun gear is connected to the planet gears, which in turn mesh with the ring gear. The arrangement and rotation of these gears determine the gear ratio and, consequently, the output speed and torque of the transmission.

- Forward and Reverse Operation:

The sun gear’s function also extends to enabling both forward and reverse operation in automatic transmissions. By controlling the engagement of the sun gear with other gears in the planetary set, the transmission can switch between forward and reverse directions.

In the forward operation, the sun gear engages with the planet gears and the ring gear, transmitting power from the input shaft to the output shaft with a specific gear ratio. In the reverse operation, the sun gear engages with a different set of gears, causing the rotation of the output shaft to reverse its direction.

- Torque Multiplication:

Another important function of the sun gear is torque multiplication. By utilizing the planetary gear set arrangement, the sun gear can multiply or reduce torque depending on the gear ratio configuration. This torque multiplication capability allows the transmission to provide higher torque output when needed, such as during acceleration or climbing steep gradients.

- Gear Shifts:

The sun gear’s function also contributes to smooth and efficient gear shifts in automatic transmissions. As gear shifts occur, the transmission control unit adjusts the engagement of the sun gear, planet gears, and ring gear to achieve the desired gear ratio for the target speed and load conditions.

During gear shifts, the engagement of clutches or bands controlled by the transmission control unit ensures that the sun gear rotates with the desired set of gears, allowing for seamless transitions between different gear ratios. This coordinated operation of the sun gear and other gears facilitates smooth acceleration and deceleration without excessively straining the transmission components.

In summary, the sun gear in automatic transmissions serves multiple functions, including power input from the torque converter, gear ratio control through its engagement with other gears, enabling forward and reverse operation, torque multiplication for increased output, and contributing to smooth gear shifts. These functions collectively allow automatic transmissions to provide efficient power transfer, dynamic gear ratios, and smooth operation in various driving conditions.

What are the advantages of using a sun gear in a planetary gear set?

The utilization of a sun gear in a planetary gear set offers several advantages, contributing to the popularity and wide range of applications of this gear configuration. Understanding the specific benefits of using a sun gear helps in appreciating its advantages in mechanical systems. Here’s an explanation of the advantages of using a sun gear in a planetary gear set:

- Torque Amplification: One of the significant advantages of a planetary gear set with a sun gear is its ability to amplify torque. By arranging the sun gear, planet gears, and an outer ring gear, torque can be multiplied or reduced depending on the specific gear ratio configuration. This torque amplification feature is particularly useful in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Compact Design: Planetary gear sets with a sun gear often enable a more compact and space-efficient design. The central positioning of the sun gear, along with the arrangement of other gears, allows for a reduction in overall size while maintaining efficient power transmission. This compactness is advantageous in applications with limited space or weight restrictions, where a smaller and lighter gear system is desirable.

- High Gear Ratios: The presence of a sun gear in a planetary gear set facilitates the attainment of high gear ratios. By manipulating the sizes and arrangements of the sun gear, planet gears, and ring gear, a wide range of gear ratios can be achieved. This flexibility in gear ratio control enables planetary gear sets to provide various output speeds and torque levels, allowing for customization based on the specific requirements of the mechanical system.

- Load Distribution: The sun gear’s engagement with multiple planet gears in a planetary gear set allows for load distribution among the gears. This distributed load-sharing characteristic helps in reducing the load on individual gears, resulting in improved reliability and longevity of the gear system. It also enables efficient power distribution and helps prevent excessive wear and stress on any single gear within the system.

- Directional Control: Planetary gear sets with a sun gear provide versatile directional control. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control feature adds flexibility to mechanical systems, allowing for a wide range of applications that require bidirectional power transmission.

- Multiple Output Shafts: Another advantage of using a sun gear in a planetary gear set is the possibility of having multiple output shafts. By incorporating additional planet gears and output shafts, a planetary gear set with a sun gear can deliver power to multiple outputs simultaneously. This feature is beneficial in applications that require power distribution to multiple subsystems or components within a complex mechanical system.

In summary, the advantages of using a sun gear in a planetary gear set include torque amplification, compact design, high gear ratios, load distribution, directional control, and the potential for multiple output shafts. These advantages make planetary gear sets with a sun gear well-suited for a wide range of applications, including automotive, aerospace, machinery, robotics, and more.

editor by CX 2023-09-07