Product Description

1.Product Description

Gear shaft, Herringbone Gear Shaft, Bevel Gear, Eccentric Shaft mainly used on vessel engine, fan internal gear

1.1. Bevel Gear, Pinion Shaft Processing

Gear drawing— Simulation Modelling—Making casting model—Casting— Primary Detection—Rough machining—Hardening Tempering—Semi-finishing machining —Hobbing—Tooth Surface Quenching—Gear grinding—Gear Surface Carburzing—Inspection—Spray Anti-rust Oil—Package—Delivery

Gear Shaft drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

2.2. Bevel Gear Package

Spray anti-rust oil on Herringbone Gear Shaft, Wrap waterproof cloth around Gear Shaft for reducer, Prepare package by shaft shape&weight to choose steel frame, steel support or wooden box etc.

1.3. OEM Customized Pinion Shaft

We supply OEM SERVICE, customized herringbone gear shaft with big module, more than 1tons big weight, more than 3m length, 42CrMo/35CrMo or your specified required material gear shaft.

2.Product Technical info.

| Module | m | Range: 5~70 |

| Gear Teeth Number | z | OEM by drawing’s technical parameters |

| Teeth Height | H | OEM by drawing’s technical parameters |

| Teeth Thickness | S | OEM by drawing’s technical parameters |

| Tooth pitch | P | OEM by drawing’s technical parameters |

| Tooth addendum | Ha | OEM by drawing’s technical parameters |

| Tooth dedendum | Hf | OEM by drawing’s technical parameters |

| Working height | h’ | OEM by drawing’s technical parameters |

| Bottom clearance | C | OEM by drawing’s technical parameters |

| Pressure Angle | α | OEM by drawing’s technical parameters |

| Helix Angle, | OEM by drawing’s technical parameters | |

| Surface hardness | HRC | Range: HRC 50~HRC63(Quenching) |

| Hardness: | HB | Range: HB150~HB280; Hardening Tempering/ Hardened Tooth Surface |

| Surface finish | Range: Ra1.6~Ra3.2 | |

| Tooth surface roughness | Ra | Range: ≥0.4 |

| Gear Accuracy Grade | Grade Range: 5-6-7-8-9 (ISO 1328) | |

| Diameter | D | Range: 1m~16m |

| Weight | Kg | Range: Min. 100kg~Max. 80tons Single Piece |

| Gear Position | Internal/External Gear | |

| Toothed Portion Shape | Spur Gear/Bevel/Spiral/Helical/Straight | |

| Shaft shape | Herringbone Gear Shaft / Gear Shaft / Eccentric Shaft / Spur Gear / Girth Gear / Gear Wheel | |

| Material | Forging/ Casting |

Forging/ Casting 45/42CrMo/40Cr or OEM |

| Manufacturing Method | Cut Gear | |

| Gear Teeth Milling | √ | |

| Gear Teeth Grinding | √ | |

| Heat Treatment | Quenching /Carburizing | |

| Sand Blasting | Null | |

| Testing | UT\MT | |

| Trademark | TOTEM/OEM | |

| Application | Gearbox, Reducer, Petroleum,Cement,Mining,Metallurgy etc. Wind driven generator,vertical mill reducer,oil rig helical gear,petroleum slurry pump gear shaft |

|

| Transport Package | Export package (wooden box, steel frame etc.) | |

| Origin | China | |

| HS Code | 8483409000 |

Material Comparison List

| STEEL CODE GRADES COMPARISON | |||||

| CHINA/GB | ISO | ГΟСТ | ASTM | JIS | DIN |

| 45 | C45E4 | 45 | 1045 | S45C | CK45 |

| 40Cr | 41Cr4 | 40X | 5140 | SCr440 | 41Cr4 |

| 20CrMo | 18CrMo4 | 20ХМ | 4118 | SCM22 | 25CrMo4 |

| 42CrMo | 42CrMo4 | 38XM | 4140 | SCM440 | 42CrMo4 |

| 20CrMnTi | 18XГT | SMK22 | |||

| 20Cr2Ni4 | 20X2H4A | ||||

| 20CrNiMo | 20CrNiMo2 | 20XHM | 8720 | SNCM220 | 21NiCrMo2 |

| 40CrNiMoA | 40XH2MA/ 40XHMA |

4340 | SNCM439 | 40NiCrMo6/ 36NiCrMo4 |

|

| 20CrNi2Mo | 20NiCrMo7 | 20XH2MA | 4320 | SNCM420 | |

3.Totem Service

CHINAMFG Machinery focus on supplying GEAR SHAFT, ECCENTRIC SHAFT, HERRINGBONE GEAR, BEVEL GEAR, INTERNAL GEAR and other parts for transmission devices & equipments(large industrial reducers & drivers). Which were mainly used in the fields of port facilities, cement, mining, metallurgical industry etc. We invested in several machine processing factories,forging factories and casting factories,relies on these strong reliable and high-quality supplier network, to let our customers worry free.

TOTEM Philosophy: Quality-No.1, Integrity- No.1, Service- No.1

24hrs Salesman on-line, guarantee quick and positive feedback. Experienced and Professional Forwarder Guarantee Log. transportation.

4.About TOTEM

1. Workshop & Processing Strength

2. Testing Facilities

3. Customer Inspection & Shipping

5. Contact Us

ZheJiang CHINAMFG Machinery Co.,Ltd

Facebook: ZheJiang Totem

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Motorcycle, Machinery, Marine, Cement |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal/External |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Bevel Wheel |

| Material: | Cast Steel |

| Customization: |

Available

| Customized Request |

|---|

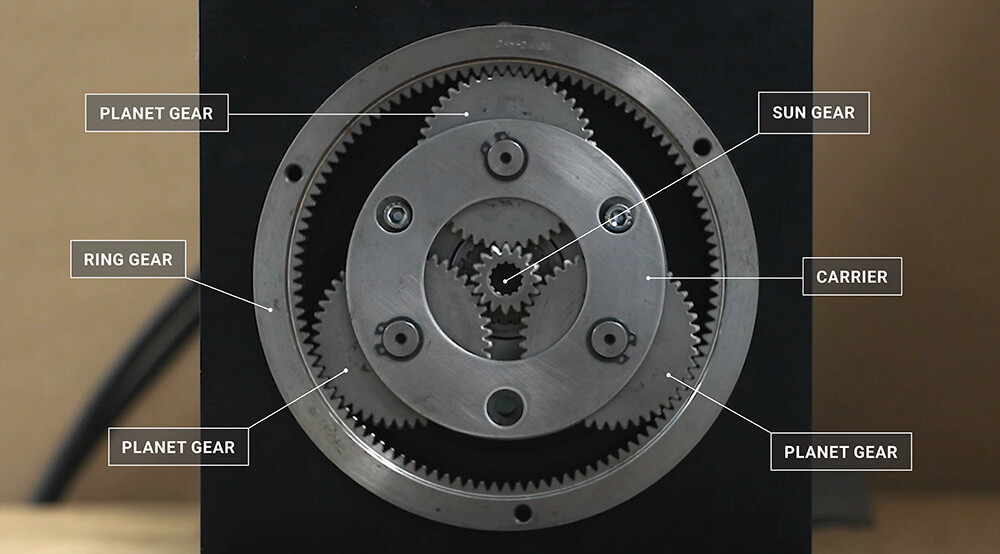

Can sun gears be used in automotive applications?

Sun gears are widely used in various automotive applications, playing crucial roles in different systems. Let’s explore the automotive applications where sun gears are commonly employed:

- Automatic Transmissions:

Sun gears are integral components of automatic transmissions in vehicles. Automatic transmissions use planetary gear systems, where the sun gear is one of the key elements. The interaction between the sun gear, planet gears, and ring gear allows for different gear ratios and smooth shifting between gears.

In automatic transmissions, the sun gear is driven by the engine’s input shaft and transmits power to the other gears. By controlling the engagement of various clutches and brakes within the transmission, the sun gear enables seamless gear changes, optimizing vehicle performance and fuel efficiency.

- Transfer Cases:

In four-wheel-drive and all-wheel-drive vehicles, transfer cases distribute power between the front and rear wheels. Sun gears are utilized in transfer cases to facilitate power transfer and gear reduction.

The sun gear, along with other gears and components, helps control the torque distribution and gear ratios between the front and rear axles. This allows vehicles to adapt to different driving conditions, such as slippery surfaces or off-road terrain, enhancing traction and stability.

- Starter Motors:

Sun gears are employed in starter motors, which are responsible for cranking the engine during startup. Starter motors use a gear reduction mechanism to convert the electric motor’s high-speed rotation into a higher torque output.

The sun gear, along with other gears like the planetary gears, enables the gear reduction necessary to generate sufficient torque to crank the engine. This gearing arrangement allows for efficient and reliable engine starting, even in challenging conditions.

- Power Seats and Windows:

Sun gears can also be found in power seat and power window mechanisms in vehicles. These systems use electric motors to adjust seat positions or operate windows.

The sun gear, along with other gears and mechanisms, converts the rotational motion of the electric motor into linear movement, enabling precise adjustments of seat positions or smooth operation of windows. The use of sun gears ensures reliable and efficient functionality of these systems.

- Other Automotive Systems:

Sun gears may also have applications in other automotive systems. For example, they can be found in power steering systems, where they contribute to the gear reduction and power transmission required for smooth steering operation.

Furthermore, sun gears can be utilized in various auxiliary systems, such as cooling fans, HVAC (heating, ventilation, and air conditioning) systems, and engine accessories. These applications leverage the sun gear’s ability to facilitate power transmission and gear reduction, enhancing the efficiency and performance of these systems.

In summary, sun gears are extensively used in automotive applications, including automatic transmissions, transfer cases, starter motors, power seats and windows, power steering systems, and auxiliary systems. Their presence in these systems enables crucial functions such as gear shifting, power distribution, gear reduction, and efficient power transmission. Sun gears contribute to the overall performance, reliability, and functionality of automotive systems, enhancing the driving experience and vehicle efficiency.

Can you explain the function of a sun gear in automatic transmissions?

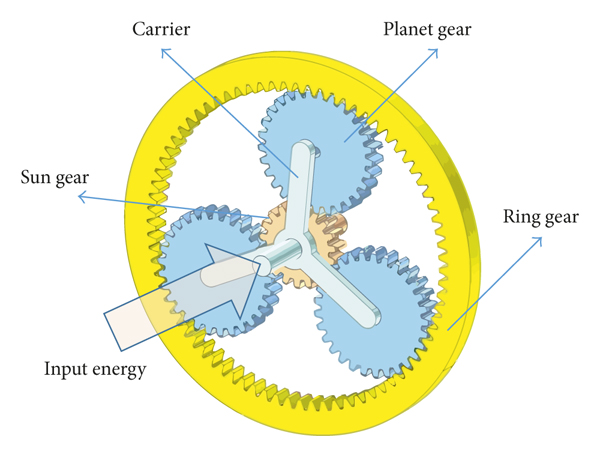

The sun gear plays a crucial role in the operation of automatic transmissions. It is an essential component within the planetary gear set, which is responsible for transmitting power and controlling gear ratios in automatic transmissions. Here’s an explanation of the function of a sun gear in automatic transmissions:

- Power Input:

The sun gear serves as one of the primary power input sources in an automatic transmission. It connects to the torque converter, which is a fluid coupling that transfers engine power to the transmission. The rotation of the sun gear receives torque from the engine and acts as the initial input for the gear set.

- Gear Ratio Control:

The sun gear, along with other gears in the planetary gear set, allows for the control of gear ratios in an automatic transmission. By varying the engagement and rotation of the sun gear, different gear ratios can be achieved, providing the desired combination of torque multiplication and speed reduction or increase.

The gear ratio control is achieved through the interaction between the sun gear, planet gears, and ring gear. The sun gear is connected to the planet gears, which in turn mesh with the ring gear. The arrangement and rotation of these gears determine the gear ratio and, consequently, the output speed and torque of the transmission.

- Forward and Reverse Operation:

The sun gear’s function also extends to enabling both forward and reverse operation in automatic transmissions. By controlling the engagement of the sun gear with other gears in the planetary set, the transmission can switch between forward and reverse directions.

In the forward operation, the sun gear engages with the planet gears and the ring gear, transmitting power from the input shaft to the output shaft with a specific gear ratio. In the reverse operation, the sun gear engages with a different set of gears, causing the rotation of the output shaft to reverse its direction.

- Torque Multiplication:

Another important function of the sun gear is torque multiplication. By utilizing the planetary gear set arrangement, the sun gear can multiply or reduce torque depending on the gear ratio configuration. This torque multiplication capability allows the transmission to provide higher torque output when needed, such as during acceleration or climbing steep gradients.

- Gear Shifts:

The sun gear’s function also contributes to smooth and efficient gear shifts in automatic transmissions. As gear shifts occur, the transmission control unit adjusts the engagement of the sun gear, planet gears, and ring gear to achieve the desired gear ratio for the target speed and load conditions.

During gear shifts, the engagement of clutches or bands controlled by the transmission control unit ensures that the sun gear rotates with the desired set of gears, allowing for seamless transitions between different gear ratios. This coordinated operation of the sun gear and other gears facilitates smooth acceleration and deceleration without excessively straining the transmission components.

In summary, the sun gear in automatic transmissions serves multiple functions, including power input from the torque converter, gear ratio control through its engagement with other gears, enabling forward and reverse operation, torque multiplication for increased output, and contributing to smooth gear shifts. These functions collectively allow automatic transmissions to provide efficient power transfer, dynamic gear ratios, and smooth operation in various driving conditions.

What are the advantages of using a sun gear in a planetary gear set?

The utilization of a sun gear in a planetary gear set offers several advantages, contributing to the popularity and wide range of applications of this gear configuration. Understanding the specific benefits of using a sun gear helps in appreciating its advantages in mechanical systems. Here’s an explanation of the advantages of using a sun gear in a planetary gear set:

- Torque Amplification: One of the significant advantages of a planetary gear set with a sun gear is its ability to amplify torque. By arranging the sun gear, planet gears, and an outer ring gear, torque can be multiplied or reduced depending on the specific gear ratio configuration. This torque amplification feature is particularly useful in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Compact Design: Planetary gear sets with a sun gear often enable a more compact and space-efficient design. The central positioning of the sun gear, along with the arrangement of other gears, allows for a reduction in overall size while maintaining efficient power transmission. This compactness is advantageous in applications with limited space or weight restrictions, where a smaller and lighter gear system is desirable.

- High Gear Ratios: The presence of a sun gear in a planetary gear set facilitates the attainment of high gear ratios. By manipulating the sizes and arrangements of the sun gear, planet gears, and ring gear, a wide range of gear ratios can be achieved. This flexibility in gear ratio control enables planetary gear sets to provide various output speeds and torque levels, allowing for customization based on the specific requirements of the mechanical system.

- Load Distribution: The sun gear’s engagement with multiple planet gears in a planetary gear set allows for load distribution among the gears. This distributed load-sharing characteristic helps in reducing the load on individual gears, resulting in improved reliability and longevity of the gear system. It also enables efficient power distribution and helps prevent excessive wear and stress on any single gear within the system.

- Directional Control: Planetary gear sets with a sun gear provide versatile directional control. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control feature adds flexibility to mechanical systems, allowing for a wide range of applications that require bidirectional power transmission.

- Multiple Output Shafts: Another advantage of using a sun gear in a planetary gear set is the possibility of having multiple output shafts. By incorporating additional planet gears and output shafts, a planetary gear set with a sun gear can deliver power to multiple outputs simultaneously. This feature is beneficial in applications that require power distribution to multiple subsystems or components within a complex mechanical system.

In summary, the advantages of using a sun gear in a planetary gear set include torque amplification, compact design, high gear ratios, load distribution, directional control, and the potential for multiple output shafts. These advantages make planetary gear sets with a sun gear well-suited for a wide range of applications, including automotive, aerospace, machinery, robotics, and more.

editor by Dream 2024-04-26